2

Twin City Engineering Supplement ES-52

. Housing.should.be.lifted.using.straps.and.spreaders..Do.

not.distort.housing.or.side.plates.when.lifting.

. Bearing.pedestals.should.be.lifted.using.straps.or.pad-

ded.chains..Under.no.circumstances.should.an.attached.or.

separated.bearing.pedestal.be.lifted.by.the.shaft,.bearings,.

drives,.motor.or.wheel.

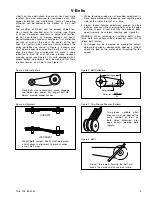

. The. shaft. and. wheel. assembly. may. be. lifted. using.

a. hoist. and. a. spreader.

with. a. sling. around. the.

shaft.at.points.nearest.the.

wheel.(see.Figure.2)..Take.

care. not. to. scratch. the.

shaft. where. the. wheel. or.

bearings. will. be. mounted..

Never. lift. or. support. the.

assembly. by. the. wheel..

Always.support.the.assem-

bly.by.the.shaft.when.lifting.

or.storing..Do.not.support.

the. shaft. or. the. wheel. on.

housing.sides..Use.only.the.

key.provided.with.the.shaft.

and.wheel.

. Wheels.shipped.separately.can.be.lifted.by.slings.run-

ning.through.the.blades.and.around.the.hub..Never.lift.the.

wheel. by. blades. or. flanges.. Always. transport. wheels. by.

lifting..Do.not.roll.the.wheel.as.this.can.damage.coatings.

and.change.the.balance.of.the.wheel.

. Bent.shafting.is.a.source.of.vibration.and.bearing.failure,.

so.handle.the.shaft.with.care..Any.scratches.on.the.shaft.

may.be.removed.with.fine.emery.cloth.or.a.stone.

Short Term Storage

If. fan. installation. is. to. be. delayed,. store. the. unit. in. a.

protected. area.. Protect. the. fan. and. motor. bearings. from.

moisture.and.vibration.(or.shock.loading).

Long Term Storage

Prior to Storage

.–.Fan.bearings.(and.motor.bearings.per.

the.motor.manufacturer’s.specifications).are.to.be.greased.

at.the.time.of.going.into.extended.storage..On.belt.drive.

units.the.belt.tension.should.be.reduced.to.less.than.half.

the.specified.value.for.the.fan’s.design.to.prevent.a.sag/

set.from.forming.in.the.shafts.and.belts.

If.the.unit.was.supplied.with.a.motor,.the.motor.windings.

should.be.measured.at.this.time.and.recorded.for

comparison.prior.to.placing.in.service..If.the.fan.housing.

was.supplied.with.a.drain.connection,.this.plug.should

be.removed.to.prevent.any.moisture.from.accumulating.in.

this.portion.of.the.unit.during.storage.

Storage Procedure

.–.Fans.should.be.stored.indoors.when-

ever. possible. where. control. over. temperature,. shock. and.

dust. is. reasonably. maintained.. If. units. are. to. be. stored.

outside. in. the. elements,. they. should. be. covered. with. a.

water-resistant. material.. The. bearings. should. be. shielded.

individually. from. water. and. dirt;. however,. do. not. tightly.

seal. to. avoid. trapping. condensation.. Stored. equipment.

should.be.stored.on.a.clean,.dry.floor.or.blocked.up.off.

the.ground.on.blocks.to.prevent.unit.from.setting.in.any.

water.or.directly.on.the.ground..If.shock.or.vibration.will.

be.present.during.storage,.the.unit.may.need.to.be.placed.

on. some. type. of. vibration. dampening. material. to. aid. in.

preventing.brinelling.of.the.bearing.surfaces.

Periodic Check

. –. On. a. monthly. interval,. the. equipment.

should.be.checked.to.ensure.that.it.has.remained.in.an.

acceptable. stored. condition.. The. fan. (and. motor. if. sup-

plied).should.be.rotated.several.times.by.hand.while.add-

ing.enough.grease.to.replenish.the.bearing.surfaces.with.

fresh.grease.and.to.maintain.a.full.bearing.cavity..Grease.

used.must.be.compatible.with.that.already.supplied.in.the.

motor. and. fan. bearings.. The. fan. impeller. should. be. left.

at. approximately. 180. degrees. from. that. of. the. previous.

month. to. prevent. the. shaft. and. impeller. from. taking. a.

set.in.one.position..Storage.records.should.be.maintained.

which.indicate.the.above.requirements.have.been.followed..

Consult.the.motor.manufacturer.for.proper.storage,.space.

heater.connection.and.lubrication.if.the.unit.was.supplied.

with.one.

Start-Up

.–.When.the.unit.is.removed.from.storage,.all.fan.

bearing.grease.should.be.purged.and.replenished.with.fresh.

grease.as.per.the.lubrication.decal..The.motor.should.be.

measured.to.verify.that.the.resistance.is.still.at.a.satisfac-

tory.level.compared.to.the.value.recorded.prior.to.storage..

Spherical. roller. bearings. with. split. pillow. block. housings.

should.be.recharged.with.grease..The.bottom.half.of.the.

housing.should.be.1/3.full.

Foundations and Supporting Structures

Floor.mounted.fans.should.be.installed.on.a.flat,.level,.rigid.

concrete.foundation.with.a.mass.at.least.three.to.five.times.

that.of.the.assembly.supported.as.a.guide,.depending.on.

the.size.and.speed.of.the.fan..Foundation.shall.be.suitable.

for. static. and. dynamic. loads. and. foundation. frequencies.

be.separated.at.least.20%.from.the.rotational.speed/speed.

ranges..The.plan.area.should.be.no.more.than.twice.that.

required.by.the.equipment..Foundations.with.larger.areas.

should. have. correspondingly. larger. mass.. Anchor. bolts.

should.be.“L”.or.“T”.shaped.with.sufficient.length.for.nuts,.

washers,. shims,. and. threads. for. draw-down.. Each. bolt.

should.be.placed.in.a.sleeve.or.pipe.with.a.diameter.larger.

than.the.bolt.to.allow.for.adjustment.

. If.the.fans.are.mounted.on.a.sub-structure,.an.inertia.

base.with.spring.isolator.system.should.be.considered.

. Fans.mounted.to.or.within.a.structure.should.be.placed.

as.close.as.possible.to.a.rigid.member.such.as.a.wall.or.

column..The.structure.must.be.designed.for.rotating.equip-

ment;.static.design.for.strength.is.not.sufficient.to.insure.

proper. operation.. Supports. for. suspended. fans. must. be.

cross-braced. to. prevent. side. sway.. Structural. resonance.

should.be.at.least.20%.from.fan.operating.speed..Vibration.

isolators.should.be.used.where.applicable.

. Any.ducting.should.have.independent.support;.do.not.

use. the. fan. to. support. ducting.. Isolating. the. fan. from.

ductwork. with. flex. connections. eliminates. transmission. of.

vibration..Fans.handling.hot.gases.require.expansion.joints.

at.both.the.inlet.and.discharge.to.prevent.excessive.loads.

caused.by.thermal.growth.

. For.fans.requiring.concrete.filled.bases.or.pedestals,.

please. refer. to. Twin. City. Fan's. installation. and. mainte-

nance. manual. "Heavy. Duty. Centrifugal. Fans. -. ES-995".

for.instructions.

Fan Installation – Factory Assembled Units

Follow.proper.handling.instructions.given.earlier.

1..Move.the.fan.to.the.final.mounting.position.

2..Remove.skid,.crates,.and.packing.materials.carefully.

3..If. supplied,. place. vibration. pads. or. isolation. base. on.

mounting.bolts..Line.up.holes.in.fan.base.with.bolts.

4..Place. fan. on. mounting. structure.. Carefully. level. unit.

using.shims.as.required.at.all.mounting.hole.locations..

Bolt.down.the.unit..Be.careful.not.to.force.the.fan.to.

conform.to.the.mounting.structure/foundation..This.may.

cause. the. bearings. to. become. misaligned. or. pinched.

causing.vibration.and.premature.failure.

5..Any.grout.may.now.be.used..Bolt.the.fan.in.position.

before. applying. grout.. Do. not. depend. upon. grout. to.

support.rotating.equipment.

6..Continue.with.Operations.Checklist.

Figure 2. Moving Shaft and

Wheel with Spreader Bar