Chapter4

Chapter4

Chapter4

Chapter4

Maintenance Mode

Maintenance Mode

Maintenance Mode

Maintenance Mode

Maintenance Mode

The settings of the printer can be changed according to its usage environment in

maintenance mode. And it is also possible to change their settings back to the initial

factory shipping setting or to adjust the cut position after printing in this mode.

And the content of the settings can be confirmed in demonstration printing mode.

To change the settings in maintenance mode, print and check the present settings.

Demonstration printing mode

Demonstration printing mode

Demonstration printing mode

Demonstration printing mode

Setting the mode

Setting the mode

Setting the mode

Setting the mode

Turning the power on while pressing the FEED switch with the front cover and the rear

cover both closed starts demonstration printing mode and the “ demonstration printing

and the present printing settings” are printed.

Setting maintenance mode

Setting maintenance mode

Setting maintenance mode

Setting maintenance mode

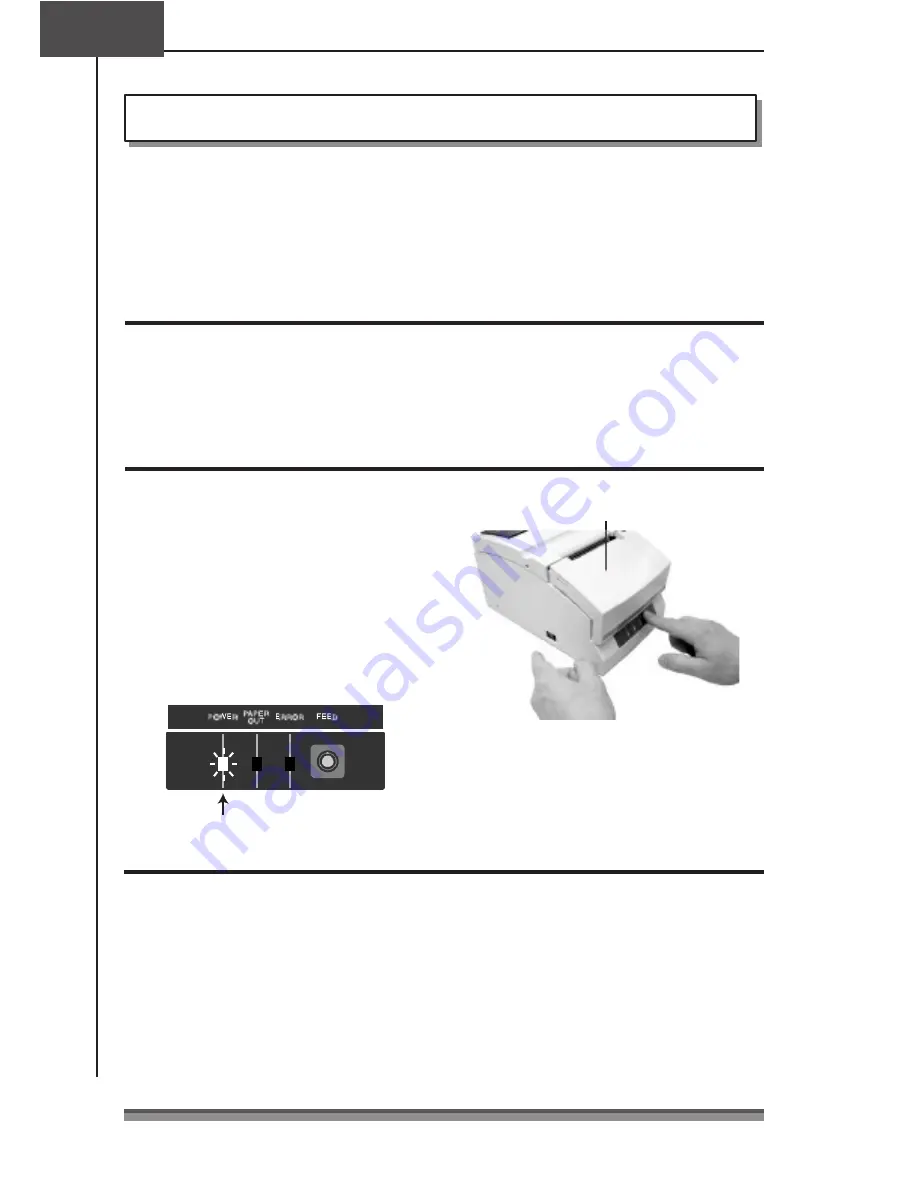

1

. Set maintenance mode by turning on

the power while pressing the FEED

switch with the front cover open and

the rear cover closed, then releasing

the FEED switch.

2

. The POWER LED flashes as the printer

enters maintenance mode.

Power switch

Front cover open

FEED switch

Close the front cover in this status.

Flashing

Types of maintenance mode

Types of maintenance mode

Types of maintenance mode

Types of maintenance mode

There are the following four types of maintenance mode.

Each mode is selected according to the number of times the FEED switch is pressed from

maintenance mode.

HEX Dump Mode: Press the FEED switch 0 times and reopen and close the front cover.

Soft SW Setting Mode: Press the FEED switch 1 time and reopen and close the front cover.

Initial Factory Shipping Mode: Press the FEED switch 2 times and reopen and close

the front cover.

Cut Position Adjustment Mode: Press the FEED switch 3 times and reopen and close

the front cover.

25

25

25

25