PREPARATION

The installation of this lift is relatively simple and can be accomplished by 2 men in a few hours. The

following tools and equipment are needed:

AW 32,46 Non-Detergent Non-Foaming Anti-Wear Hydraulic Oil SAE-10 (12 quarts)

Chalk line and 12’ Tape Measure, Transit and a 4’ Level

Rotary Hammer Drill with 3/4” Masonry Drill Bit. Core Drill Rebar Cutter, Hammer and

Hex-Key / Allen Wrench Set

Sockets and Open Wrench set, 1/2” thru 1-1/2”(1-1/8” for 5/8” Anchors)

Medium Crescent Wrench and Medium Pipe Wrench

Crow Bar for Shim Installation, Medium Flat Screwdriver and Cross Screwdriver.

Vise Grips and Needle Nose Pliers

GENERAL INFORMATION

1.

Carefully remove the crating and packing materials. CAUTION! Be careful when

cutting steel banding material as items may become loose and fall causing personal

harm or injury.

2.

Identify the components and check for damage or shortages. If damage or shortages

are discovered, contact distributor immediately.

Save the shipping bolts for use in the

installation

.

Packing:

*The lift is packed into one heavy rack and one carton box on it.

*Every rack has two runways, four columns with covers, two cross bars, two ramps, two

front stops, one long lock linkage rod, and a accessory box.

3.

Lift location - check with building owner and / or architect’s building plans when applicable. The lift

should be located on a relatively level floor with concrete sufficiently cured.

Suggestion:

(1) The floor be flat and without gradients (maximum of 10mm tolerance between the two base

plate of the columns)

(2)

There are no cracks within 38” and no seams within 6” of the base plate.

(3)

The concrete is recommended with following dimension: 157.5”L * 39.5”W * 7.75”H.

Remember any structure is only as strong as the foundation on which it is located.

4.

Check for ceiling clearance.

Suggestion:

At least 5” left between the top of a car on the lift and the ceiling.

Check for clearance in the front and rear of vehicle when on lift - will the garage door open

and close properly.

Suggestion:

At least 24” space left between the edge of the column and the wall.

At least 144” space left between the central line of the columns and the wall.

( At least 36” space for walking left between the front or the rear of the vehicle and the

wall. )

4

REV A-083013

Summary of Contents for FP12K-K

Page 2: ......

Page 6: ...REV A 083013 ...

Page 8: ...REV A 083013 ...

Page 9: ...REV A 083013 ...

Page 11: ...REV A 083013 ...

Page 14: ...REV A 083013 ...

Page 15: ...REV A 083013 ...

Page 16: ...REV A 083013 ...

Page 17: ...REV A 083013 ...

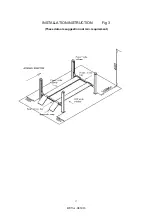

Page 20: ...INSTALLATION INSTRUCTION Fig 3 These data are suggestion not min requirement 17 REV A 083013 ...

Page 21: ...INSTALLATION INSTRUCTION Fig 20 18 REV A 083013 ...

Page 22: ...INSTALLATION INSTRUCTION Fig 21 19 REV A 083013 ...

Page 27: ......