to size the wire for a 25 amp circuit.

STEP 7

: (Routing the CABLES)

1. Check again that all the cables are on the pulleys both of the columns and underneath the

power-side runway.

2. Make sure that the current of the power supply is enough for the motor.

3. Press the start button on the motor to raise the runways a little. Make sure that the safety latches

are not resting on the racks.

4. Screw the nut up or down on the column top to level the cross bar and runway.

The cables should be checked weekly for equal tension. Failure to do this will cause uneven lifting. The

cables should always be adjusted so that they are equal tension when the cross bars are resting on the

safety locks.

IMPORTANT NOTE

STEP 8

: (Mounting on accessories)

1. Mount the front stops. (See fig. 18)

2. Connect the long linkage rod from Front cross bar to rear cross bar. Make sure the safety locks

are working correctly.

3. Route the hydraulic hose underneath the power-side runway.

4. Mount on the approaching ramps.

5. Put the column covers on the column.

STEP 9

: (Lift start up)

1. Do not place any vehicle on the lift at this time!

2. Cycle the lift up and down several times to insure latch click together and all air is removed from the

system.

3. To lower the lift, the latch releases must be manually released while the lowering handle of the

pump is pressed. Latches will automatically reset once the lift ascends approximately 17" from

the base.

OPERATION

RAISE-LIFT

1.

Press button on power unit

The latch mechanism will ‘trip over’ when the lift raises and drop into each latch stop. But, to lock the lift

you must press the lowering handle to relieve the hydraulic pressure and let the latch set tight in a lock

position.

Always lock the lift before going under the vehicle. Never allow anyone to go under the lift when

raising or lowering. Read the safety procedures in the manual.

10

REV A-083013

Summary of Contents for FP12K-K

Page 2: ......

Page 6: ...REV A 083013 ...

Page 8: ...REV A 083013 ...

Page 9: ...REV A 083013 ...

Page 11: ...REV A 083013 ...

Page 14: ...REV A 083013 ...

Page 15: ...REV A 083013 ...

Page 16: ...REV A 083013 ...

Page 17: ...REV A 083013 ...

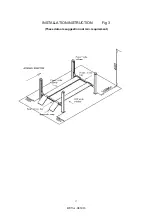

Page 20: ...INSTALLATION INSTRUCTION Fig 3 These data are suggestion not min requirement 17 REV A 083013 ...

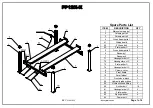

Page 21: ...INSTALLATION INSTRUCTION Fig 20 18 REV A 083013 ...

Page 22: ...INSTALLATION INSTRUCTION Fig 21 19 REV A 083013 ...

Page 27: ......