Service Manual 73

Page 7 of 32

Do not over-tighten. Packing is designed to keep leakage to a slight weep. Normally 2-3 drops

per minute is acceptable.

If excessive leakage persists after complete adjustment, consider re-packing the stuffing box or

using another packing type.

Lubrication Requirements

Outer Bearing

The standard outer bearings are maintenance-free. They are greased and sealed by the

manufacturer.

Optional high temperature outer bearings must be re-lubricated at least every 250 hours or 30

days.

Bracket Bushing

Bracket bushings that do not have grease fittings are fully lubricated by the pumped fluid and are

maintenance-free.

Bracket bushings that are provided with grease fittings must be re-lubricated at least every 500

hours or 60 days.

Idler Bushing

Idler bushings that are used with standard solid idler pins are fully lubricated by the pumped fluid

and are maintenance-free.

Idler bushings that are used with optional greasable idler pins must be re-lubricated at least every

500 hours or 60 days.

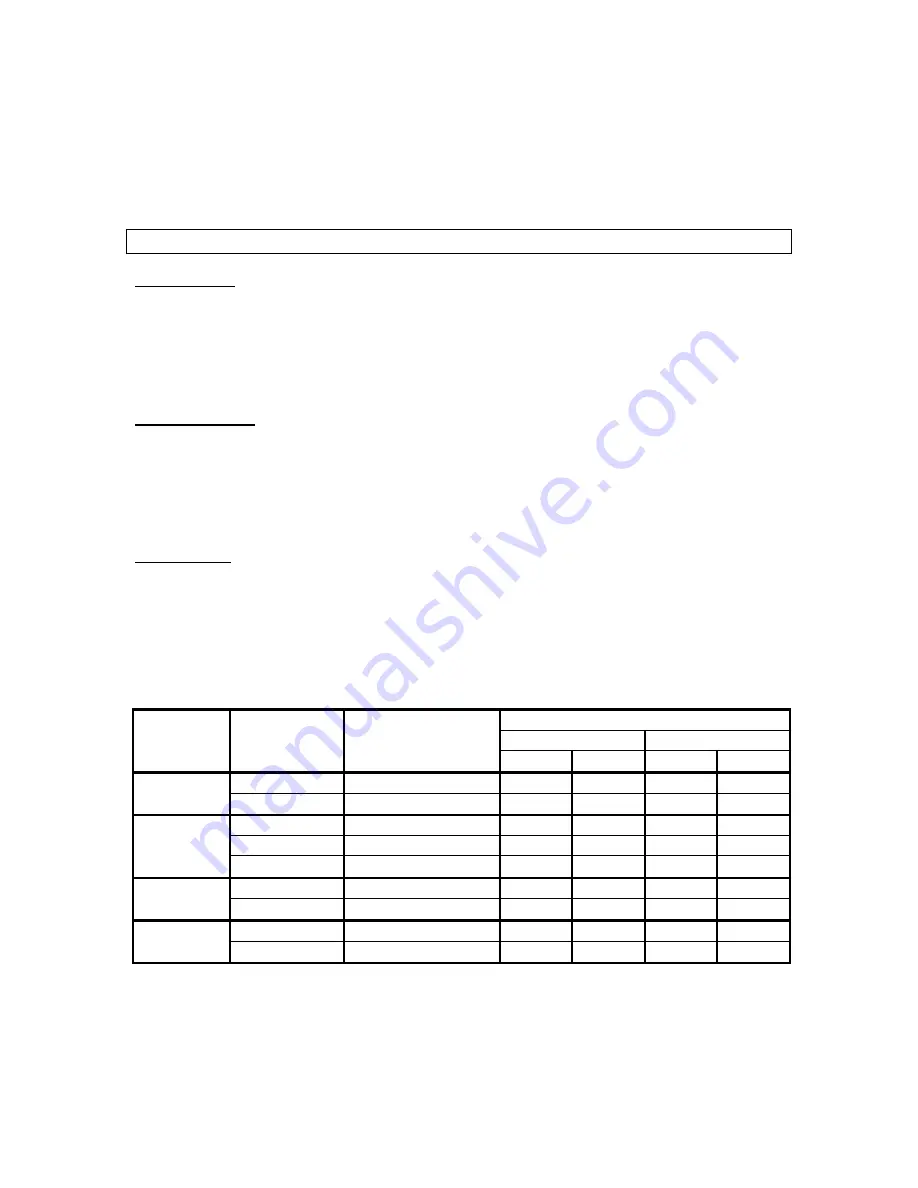

Recommended Lubricants

Recommended Temperature Range

Minimum

Maximum

Description Manufacturer

Grade

Deg. F

Deg. C

Deg. F

Deg. C

Lubriplate

1200-2

-25

-32

350

177

standard

grease

Mobil

Mobilith AW 2

-25

-32

350

177

Lubriplate

HIGH-TEMP

40

4

500

260

Lubriplate

930-AA

0

-18

400

204

high

temperature

grease

Mobil

Mobilith SHC PM

0

-18

450

232

Lubriplate

MAG-1

-60

-51

200

93

low temp.

grease

Mobil

Mobiltemp SHC 32

-60

-51

200

93

Lubriplate

FGL-2

10

-12

350

177

food grade

grease

Mobil

Mobilgrease FM 102

10

-12

350

177

NOTE:

This lubrication data is only intended as a guide. Some applications may have different

lubrication requirements, depending on actual conditions.

Table 2 – Recommended Lubricants