- 8 -

Terminal

Description

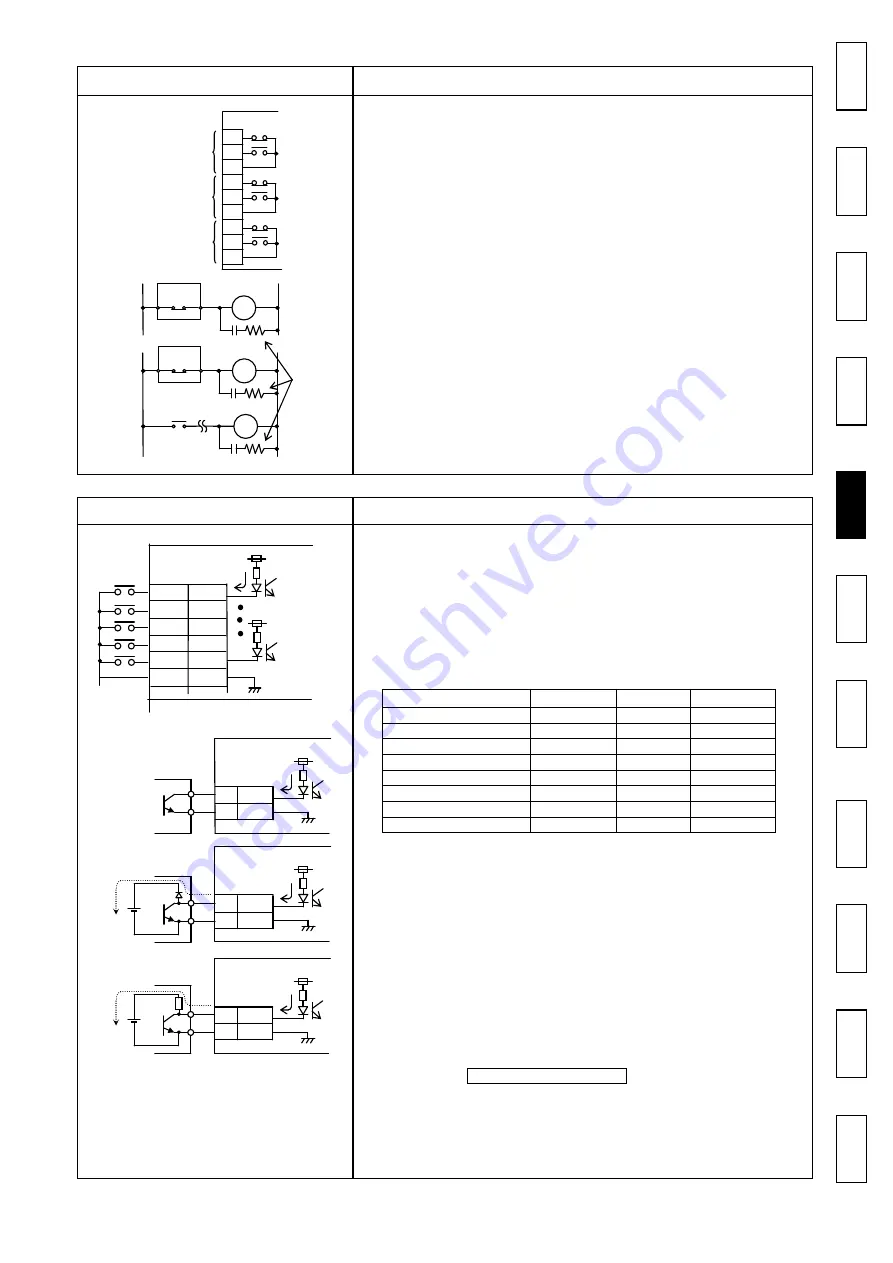

[Output relay]

● Output relay OUT1 (Terminals 4, 5, 6), OUT2

(Terminals 7, 8, 9), OUT3 (Terminals 13, 14, 15)

・

Output terminals used to notify external devices of

an alarm or overload condition. Three relay signals,

OUT1, OUT2, and OUT3 will be output.

Contact specification: 1c contact: 250 VAC, 0.5A

Contact specification: 1c contact: 250 VAC, 0.5A

Contact specification: 1c contact: 250 VAC, 0.5A

Contact specification: 1c contact: 250 VAC, 0.5A

(Inductive load cosφ = 0.4)

(Inductive load cosφ = 0.4)

(Inductive load cosφ = 0.4)

(Inductive load cosφ = 0.4)

Notes:

・

When an electromagnetic contactor is connected as shown

in the left figure

①

, limit the operating coil capacity to

less than 100 VA at power-on and to less than 10 VA

during retention. If an electromagnetic contactor with

larger capacity is connected, activate an auxiliary relay

with the output of the Shock Monitor as shown in the left

figure

②

, and then open/close the electromagnetic

contactor with the contact of the auxiliary relay.

・

As shown in the left figure, mount a CR absorber to

the coils of the electromagnetic contactor and

auxiliary relay to prevent noise generation.

・

When a sequencer photocoupler input which operates

with minute current (10 mA or less) is connected, activate

a relay for minute current with a relay output, and then

connect the contact of the relay for minute current to a

sequencer photocoupler input.

8.2 Connector CN1

Terminal

Description

[Contact input]

[Non-contact input]

● X1, X2, X3 (CN1 pin Nos. 1, 9, 2)

These terminals are used to externally switch preset

overload detection levels according to the load

condition of the equipment. The level can be switched

according to the load condition which varies depending

on the selected motor speed, material, process, etc.

Up to eight detection levels can be selected by using the

combination of the ON (short-circuit) and OFF (open)

statuses of terminals X1 to X3. Three individual settings

for OUT1 - OUT3 can be set for each selection No.

If a number larger than the value set for parameter

“5: Process” (No. of selected levels, refer to page 16)

is chosen, the selection will be [1].

● X4 (CN1 pin No. 10)

While the section between X4 and CM is

short-circuited, the load detection is stopped.

● X5 (CN1 pin No. 11)

When the section between X1 and CM is

short-circuited (turned ON), the integration of the

power starts.

Two integration methods are available: To integrate

the power while the section is turned ON; or to

integrate the power for the setting time after the

section is turned ON. This can be set with

parameter 3: Integration Time.

Note:

When setting [Non-contact input], be sure to use an

open collector signal shown in the left figure

①

.

Using

②

or

③

may cause malfunction due to a

detour circuit which may be created depending on the

condition of the power supply.

OUT1

OUT2

7

8

9

4

5

6

TSM4000

OUT3

14

13

15

Process No.

X1 - CM

X2 - CM

X3 - CM

Process [1]

OFF

OFF

OFF

Process [2]

ON

OFF

OFF

Process [3]

OFF

ON

OFF

Process [4]

ON

ON

OFF

Process [5]

OFF

OFF

ON

Process [6]

ON

OFF

ON

Process [7]

OFF

ON

ON

Process [8]

ON

ON

ON

①

②

X1

1

+12 V

TSM4000

CM

4

TSM4000

①

○

○

○

○

②

×

×

×

×

③

×

×

×

×

X1

1

CM

4

+12 V

X1

1

CM

4

+12 V

TSM4000

X1

1

X2

9

X3

2

10

4

X5

10 mA

+12 V

TSM4000

X4

11

CM

C

o

n

te

n

ts

U

s

a

g

e

/N

a

m

e

s

S

a

fe

ty

In

st

al

la

tio

n

/W

ir

in

g

T

er

m

in

a

ls

T

er

m

in

a

ls

T

er

m

in

a

ls

T

er

m

in

a

ls

C

on

n

ec

tio

n

O

p

e

r

a

ti

o

n

M

ai

n

te

n

an

ce

/In

sp

ec

tio

n

Sp

ec

ifi

ca

tio

ns

D

im

en

si

on

s

W

a

r

r

a

n

ty

CR

absorber

AR

MC

A R

T SM 4 0 0 0

EM contactor

Aux. relay

M C

T SM 4 0 0 0

EM contactor

Summary of Contents for TSM4000M2

Page 27: ...MEMO MEMO MEMO MEMO...