- 6 -

⑥

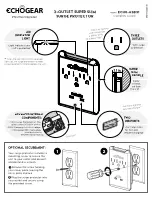

Current sensor

To detect motor current, pass the V-phase motor wire through

the sensor in the direction from the power supply side to

motor side as shown by the arrow. Make sure that the

direction of the wire matches with the arrow on the top of the

current sensor. The number of times to pass the wire through

the sensor depends on the motor capacity and voltage. Refer to

the following table for the specified number.

The figure on the left shows the case where the number of

times to pass the wire through the sensor is two (2).

(Note) Refer to the connection diagrams on pages 10 and 11 for

the current sensor wiring and be sure to pass through the motor

wire of the correct phase which is connected with the voltage

input terminal V[2] of the TSM4000. If the wire of the other

phase is connected, or the wire is passed through in the opposite

direction, the electric power cannot be detected properly. This

wiring is unrelated to the positive/reverse phase of the power

supply or of the forward/reverse rotation switching of the motor.

■ Number of times to pass the wire through the sensor

Motor

capacity

(kW)

200/220 VAC motor

400/440 VAC motor

Motor

rated

current (A)

Sensor

model No.

No. of times to

pass wire

through sensor

Motor

rated

current (A)

Sensor

model No.

No. of times to

pass wire

through sensor

0.1

0.71

TSM-U010

6

0.36

TSM-U010

12

0.2

1.4

TSM-U010

3

0.70

TSM-U010

6

0.4

2.3

TSM-U010

2

1.2

TSM-U010

3

0.75

3.6

TSM-U050

6

1.8

TSM-U010

2

1.5

6.6

TSM-U050

3

3.3

TSM-U050

6

2.2

9.2

TSM-U050

2

4.6

TSM-U050

5

3.7

15

TSM-U050

1

7.5

TSM-U050

3

5.5

22

TSM-U050

1

11

TSM-U050

2

7.5

29

TSM-U100

1

15

TSM-U050

1

11

42

TSM-U100

1

21

TSM-U050

1

15

55

TSM-U150

1

28

TSM-U100

1

18.5

67

TSM-U150

1

34

TSM-U100

1

22

78

TSM-U200

1

39

TSM-U100

1

30

107

TSM-M300

1

54

TSM-U150

1

37

132

TSM-M300

1

66

TSM-U150

1

45

160

TSM-M400

1

80

TSM-U200

1

55

198

TSM-M600

1

99

TSM-M300

1

75

270

TSM-M600

1

135

TSM-M300

1

90

320

TSM-M800

1

160

TSM-M400

1

110

384

TSM-M800

1

192

TSM-M400

1

The motor rated current values in the table are for reference only.

■ Connecting the sensor cable to the main unit

Connect the sensor cable TSM4-S01 included in the package properly to the current

sensor and Shock Monitor main unit respectively. If the cable length is insufficient,

longer cables are optionally available. Refer to page 4 for the model number of the

sensor cable and contact TEM for ordering.

M

o

to

r

s

id

e

P

o

w

e

r

su

p

p

ly

s

id

e

C

o

n

te

n

ts

U

s

a

g

e

/N

a

m

e

s

S

a

fe

ty

In

st

al

la

tio

n

In

st

al

la

tio

n

In

st

al

la

tio

n

In

st

al

la

tio

n

/W

ir

in

g

/W

ir

in

g

/W

ir

in

g

/W

ir

in

g

T

er

m

in

a

ls

C

on

n

ec

tio

n

O

p

e

r

a

ti

o

n

M

ai

n

te

n

an

ce

/In

sp

ec

tio

n

Sp

ec

ifi

ca

tio

ns

D

im

en

si

on

s

W

a

r

r

a

n

ty

V-phase

Note)

Summary of Contents for TSM4000M1

Page 26: ...MEMO MEMO MEMO MEMO...

Page 27: ...MEMO MEMO MEMO MEMO...