5

5. Installation

1. Environmental specifications

Install the Shock Relay in the following environment.

•

Temperature:

-

20 to

+

60

℃

not in direct sunlight.

•

Humidity

:

45

~

85% relative humidity without condensation and freezing.

•

Place

:

Indoors, no water splash.

•

Atmosphere

:

Free from t dust, corrosion gas, and oil mist.

•

Height: 2000m or less above sea level.

•

Vibration: 5.9m/s

2

and under.

2. Installation to the panel

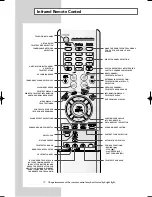

(1) Installation with DIN rail

While pulling the hook of Shock Relay to the arrow direction, install Shock Relay

to 35mm DIN rail. When removal, put the hook to the arrow direction with

flathead screwdriver.

(2) Installation with screw

Put the plate for installation at the both side or Shock Relay, and install Shock

Relay to the panel

3. Installation to the DIN rail

(1) Pull the hook on the Shock Relay in the direction of the arrow to remove the

mounting bracket.

(2) Install the Shock Relay to the DIN rail.

6. Wiring

(1) Connect 90

-

250VAC power source to the terminal A1, A2.

Never connect the output of an inverter or a servo driver to terminals A1-A2.

Install an insulation transformer between the power line and terminals A1-A2 of

the SHOCK RELAY when harmonic noise is included in the power line.

(2) Check and correct the following items before turning the power on.

a. Is there any misconnection?

b. Have you forgotten to complete any connections?

c. Are there any abnormal conditions such as a short-circuit or ground fault?

WARNING

ELECTRICAL SHOCK AND BURN

Do not operate without the ground wire connected.

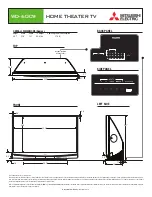

7. Terminal Function

Terminal Function

.

Contents.

A1

A2

Power

Supply

100 – 240VAC commercial power supply is wired

95

Common

96

Normally close

(Tripped: open)

98

Output

Relay

Normally open

(Tripped: close)

!

!

!

!

Pull a hook in the direction of the arrow with a screwdriver to

remove the bracket.

Mounting hole

hook

63

2-M4

Attachment

A1

A2

95

96

98