6. Maintenance

This session presents the clean tools and methods to maintain your printer.

1. Please use one of following material to clean the printer.

Cotton swab (

Head cleaner pen

)

Lint-free

cloth

Vacuum / Blower brush

100%

ethanol

2. The cleaning process is described as following

Printer Part

Method

Interval

1. Always turn off the printer

before cleaning the printhead.

2. Allow the printhead to cool for a

minimum of one minute.

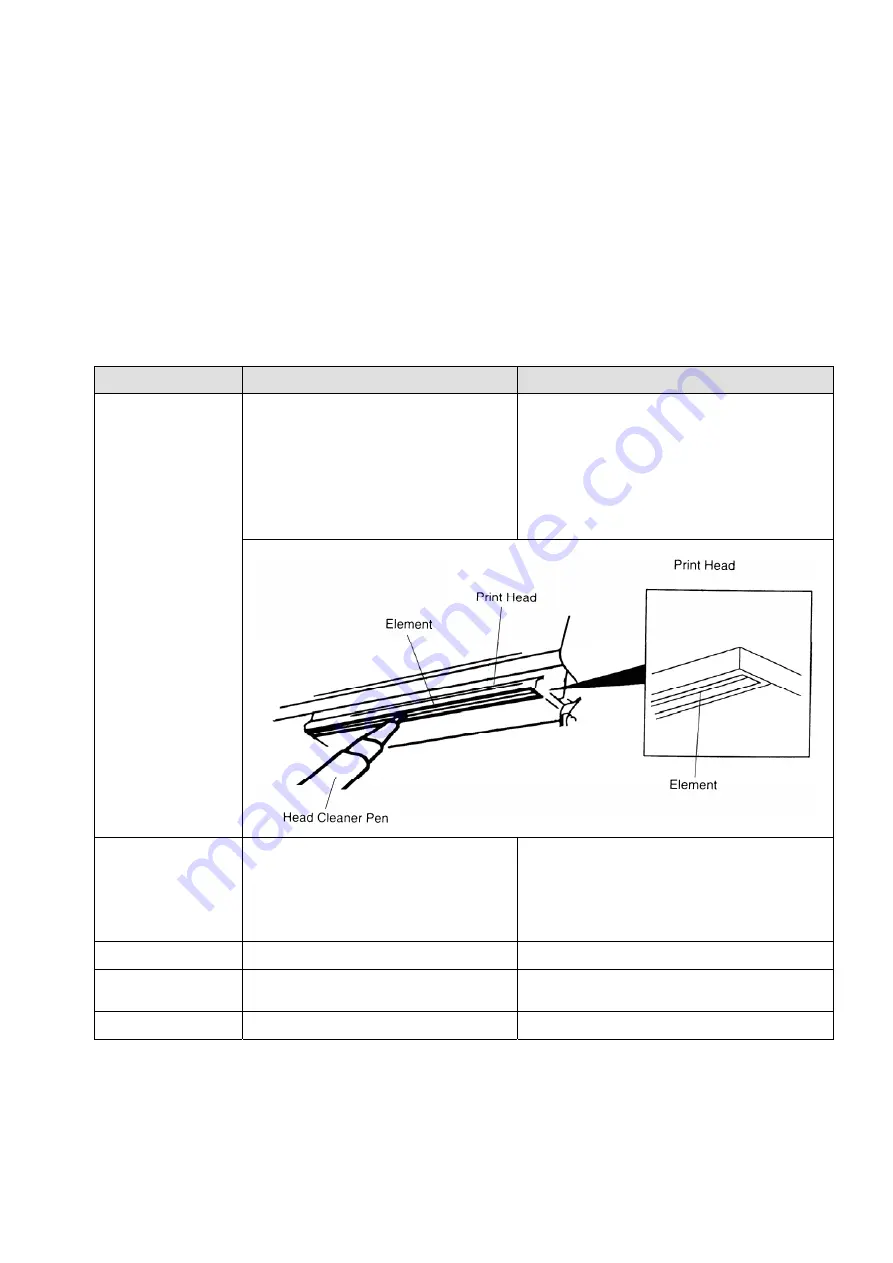

3. Use a cotton swab (Head

cleaner pen) and 100% ethanol

to clean the printhead surface.

Clean the printhead when changing a

new label roll

Printhead

Platen Roller

1. Turn the power off.

2. Rotate the platen roller and

wipe it thoroughly with 100%

ethanol and a cotton swab, or

lint-free cloth.

Clean the platen roller when changing

a new label roll

Sensor

Compressed air or vacuum

Monthly

Exterior

Wipe it with water-dampened

cloth

As needed

Interior

Brush or vacuum

As needed

Note:

z

Do not touch printer head by hand. If you touch it careless, please use ethanol to clean

it.

53