5

other factors affecting the power tool work safety. If any damage

spontaneous combustion of sanding dust in the dust bag (

6

). Elevated

to the power tool is detected, it should be repaired before use.

danger exists when such a dust is mixed with residues of lacquer,

Improper power tool maintenance is a reason for many accidents.

polyurethane or other chemical materials, and the ground material is

heated after prolonged grinding. Therefore it is necessary to avoid over-

f)

Cutting tools should be sharp and clean.

Keeping sharp cutting

edges in good condition reduces the risk of jamming and facilitates

heating of the ground material and the grinder, and the dust bag must

operation.

always be emptied during breaks and after completion of the work.

g)

Power tools, equipment, working tools etc. should be used

d)

Workplace must be kept clean.

Mixtures of materials are especially

according to this user's manual taking into account operating

dangerous. Light metal dust can ignite or explode.

conditions and the work to be done.

Misusing a power tool can

e)

Aspiration of grinding dust is harmful to health. Direct

result in dangerous situations.

physical contact with dusts or their penetration to lungs can

h)

At low temperatures and after a long brakes in operation it is

cause allergic reactions and/or respiratory system diseases of

recommended to turn the power tool to operate it with no

the operator or persons in the vicinity. Some materials, e.g.

load for a few minutes to provide proper grease distribution

paint coatings with lead content, contain potentially toxic

inside its driving mechanism.

chemical substances. In order to reduce the impact of these

i)

Use soft, damp (cannot be wet) cloth and soap to clean power

substances, the workplace must be always well ventilated,

tools. Do not use petrol, solvents and other agents that may

and tested and safe protective measures must be used, such

damage your equipment

.

as safety dust filter masks with a P2 class absorber designed

j)

Power tools can be stored/carried after making sure that all

especially for filtering microscopic particles.

Dust extraction

moving components are locked and protected against release

should be used, if only possible.

with original devices intended for this purpose.

f)

Safety goggles must always be used in order to prevent dust

k)

Store power tools in a dry, dust and water-protected place.

from getting into eyes.

l)

Carry your power tool in its original packaging to provide

g)

Ear protection means (earmuffs, earplugs) must be used.

protection against mechanical damage.

h)

Safety gloves must be used, and the abrasive belt must never

m)

Keep handles and grip surfaces clean and free from oil and

be touched when in motion.

This can cause hand injury.

grease.

Secure grip and control over the tool in unexpected

i)

During operation, the tool should be held firmly with both

circumstances are impossible if handles and grip surfaces are slippery.

hands.

WARNING! General warnings regarding the use of

j)

Damaged, used up or heavily fouled abrasive belts must not

power tools.

be used.

Damaged abrasive belts can break, be rejected and cause

Repair

:

injury.

k)

The sander must be powered ON and OFF only when the

abrasive belt (10) does not touch the surface of processed

material, otherwise the tool can be wrenched from hands.

CONSTRUCTION AND INTENDED USE OF THE GRINDER:

The belt sander is a handheld power tool driven by a single-phase

commutator motor. It is a device of the second class of equipment (double

insulation).

The sander is intended for dry grinding wooden, wood-based, metal and

plastic surfaces.

Do not use for asbestos or materials containing graphite.

WARNING!

Do not use for drywall (gypsum board joints) and similar materials. Fine

BELT

, detailed guidelines related to safe

dust penetrating internal parts of the machine causes blockage of

operation of the device:

ventilation spaces and leads to motor overheating and damage.

a)

Belt sander, hereinafter called the «sander», is not a

The tool must not be used for works requiring the use of a

waterproof device, it must be used for dry sanding only.

Water

professional device.

Every use of the sander other than the intended

penetrating into the handheld power tool can cause electrocution.

use described above is forbidden and will cause loss of warranty and

b)

During operation, when the handheld power tool can come

rejection of responsibility of the manufacturer for any resulting damage.

into contact with energized power cables or its own power

Any modifications of the device introduced by the user relieve the

cord, it must be held by insulated surfaces intended for this

manufacturer from any responsibility for damages and losses incurred by

purpose.

Contact with "energized cables" can also cause "energizing" of

the user and the surroundings.

metal parts of the handheld power tool causing electrocution of its

operator.

c)

Sanding metal causes creation of sparks. Care must taken, so

the sparks created during sanding do not constitute any

threat to persons, and all flammable materials must be

removed from the surrounding area.

Sparking can also cause

a)

carried out by PROFIX Service, which guarantees the best

quality or repair and use of genuine spare parts.

b)

If a fixed power cord is damaged, to avoid risks it should be

replaced by power tool manufacturer or in a specialty repair

shop or by a qualified person.

WARNING!

While operating power tools it is necessary to observe basic

work safety rules to avoid fire, electric shock or mechanical

injury.

SANDER

Application of the tool in accordance with the intended use also refers to

its maintenance, storage, transportation and repairs.

Defective electric tools can be handed over for repairs exclusively to

service workshops appointed by the tool manufacturer. The tools supplied

from electric grid shall be repaired exclusively by authorized

Warranty and post-warranty repairs of its power tools are

Summary of Contents for TMT810

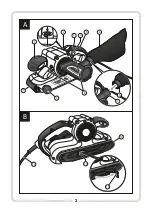

Page 2: ...2 B A 11 5 6 7 1 2 3 4 5 6 810W 9 10 12 11 6 5 8 10...

Page 3: ...3 D C 13 P 1 2 0 10 11 10 9...

Page 13: ...13 TMT810 TMT810K RCD 30 RCD...

Page 14: ...14 a a PROFIX...

Page 15: ...15 2 a 10 6...

Page 17: ...17 4 4 11 3 3 n 4 D 3 n 10 2 6 9 n n n n 8 1 11 10 B 2 2 13 6 6 3 10 13 5 C 3 810K 12...

Page 18: ...PROFIX 18 n 03 228 34...

Page 44: ...www profix com pl...