16

Tool assembly

E464EN_04.DOC

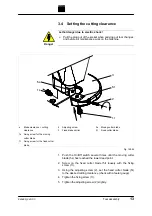

1. Push the turning handle when the machine is either running or

switched off and rotate it.

2. The turning handle locks into place when it is released.

3. Marker points have been placed on the turning handle (27)

which are to be positioned in accordance with sheet thickness

and the particular application to be carried out.

4. Altering the clearance between the two blades allows

optimisation of cutting behaviour to match particular

applications.

Note

3

(+)

intermediate stage in direction of rotation 2

(-)

intermediate stage in direction of rotation 1

Sheet thickness

[mm]

Setting of the

turning handle

for the cutting of

curves

Setting of the

turning handle

for the cutting of

straight lines

Setting of the

turning handle

for the cutting of

coils

3.5 3(+) 3(+) -

3.0 3(+) 3 1

2.5 3 2(+) 1

2.0 2(+) 2 1

1.5 2 1(+) 1

1.0 1(+) 1 1

0.5 1 1(-) 1(-)

3

The settings listed in the Table are recommended values.

Changing the height

clearance between moving

cutter blade and fixed

cutter blade

Table 5