E211en1_2.doc

N700-1

GB

8

Motor bearing l u b r i c a t i o n

The ball bearing in the motor flange is to be lubricated

via the lubricating head using a grease gun.

Lubricating interval:

every 10 operating hours

Recommended

greases:

BP Energrease LS-EP 2

SHELL Alvania Grease EP 2

Cleaning

Clean the filter 355 every 10 operating hours in order

to prevent throttling or power loss.

See the spare parts list for an diagram of filter

355.

Speed limiter and ball bearing are to be lubricated

with gear grease during regular machine mainte-

nance.

Warning:

Speed limiter 324 is to be handled with

particular care, as damage can cause overspeed.

See diagram in the spare parts list.

Changing vanes

The performance of the machine decreases if the

vanes are excessively worn.

Vane replacement and all other repair work is to be

carried out by an expert!

Vane set (4) on the rotor of the compressed-

air motor. See Item 310 in the spare parts list

for corresponding diagram.

Repairs

Danger of injury

Pneumatic tools conform to the applicable

safety regulations. Repairs may only be

carried out by qualified electricians in order

to prevent unnecessary accidents.

Use only o r i g i n a l s p a r e p a r t s.

Please note the specifications on the output plate.

You will find a list of TRUMPF representatives

at the back of this operating manual.

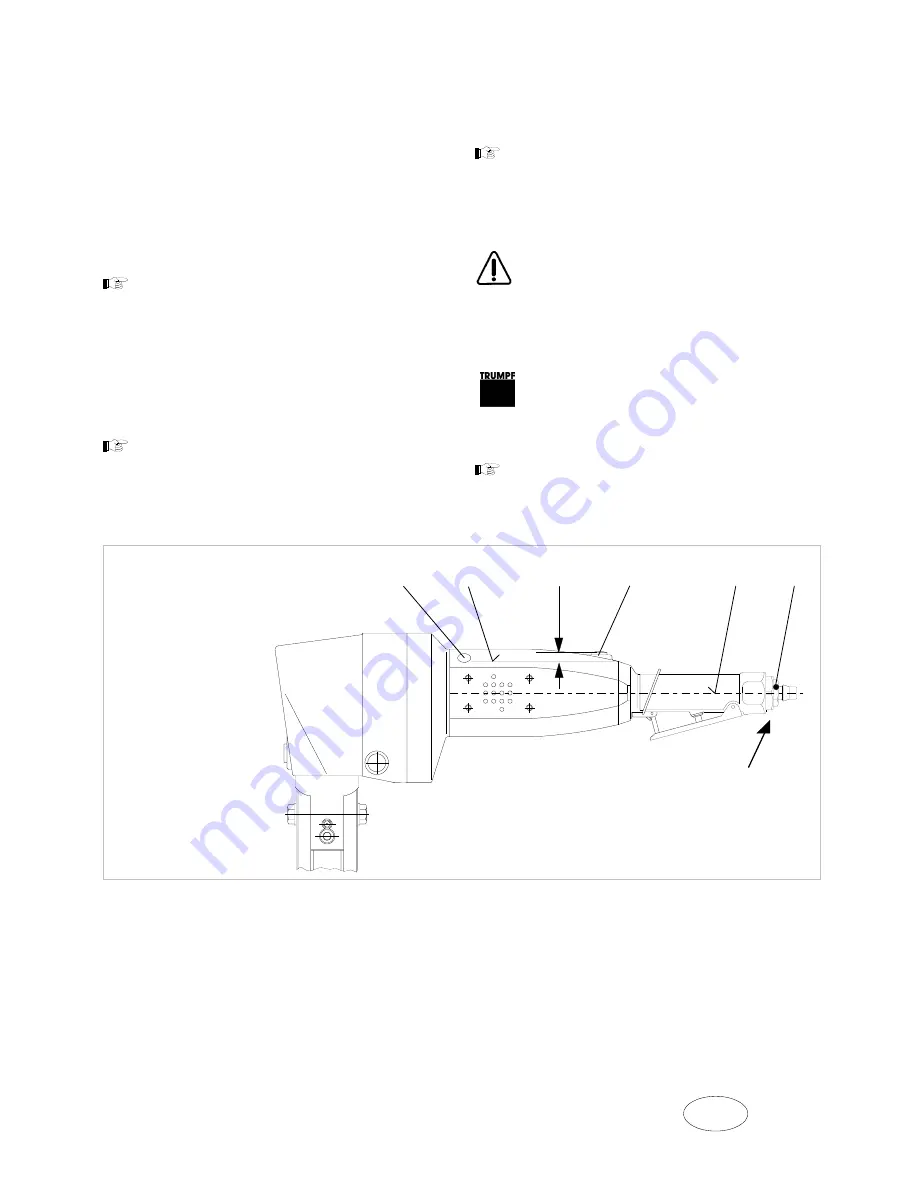

Fig. 10776

312 Lubricating head for

motor bearing lubrication

313 Sealing screw of oil filler

neck

314 O-ring (9.2 x 1.8) under

the sealing screw

355 Filter

358 Quick-release coupling

M

center machine axle

max.Maximum oil level when

refilling oil (15 mm under

the filler neck when the

center axle is horizontal)

Note: If the oil level is

too high, oil will spill out

of the motor housing

exhaust opening

312

max.

15mm

M

358

355

313

314

Summary of Contents for N700-1

Page 1: ...Operator s manual english N 700 1...

Page 2: ......

Page 12: ...E211en1_2 doc N 700 1 GB 10...