20

Original accessories and wearing parts

E517EN_03.DOC

6.

Original accessories and wearing parts

Designation

Original

acces-

sories

deli-

vered

Wearing

parts

Optio-

nal

Material-

number

Guide

rail

+ + 920881

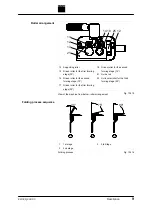

Driver roller 30°

+

+

135477

Driver roller 75°

+

+

135478

Roller

(horizontal)

+ + 135791

Suspension

eyelet

+

107666

Allen key DIN 911-4

+

067849

Universal oil (0.1 litre)

+

138648

Case

+

982582

Moulding (aid for the pre-forming

of the suspension lug

→

lock

seam preparation)

+

136688

Operator's

manual

+

1254076

Safety information (red

document), other countries

+

125699

Safety information (red

document), USA

+

1239438

Original accessories, wearing parts and optional items

To ensure fast delivery of the correct original and wearing parts:

1. Give the order number.

2. Enter further order data:

–

Tension data

–

Number of pieces

–

Machine type

3. Give complete dispatch data:

–

Correct address.

–

Required delivery type (e.g. air mail, courier, express mail,

ordinary freight, parcel post).

4. Send the order to the TRUMPF representative office. For

TRUMPF service addresses, see the address list at the end of

the document.

Tab. 6

Ordering wearing parts