13 Manual Number 9017942 • Revision K, May 14, 2020

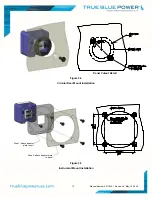

Step 4: place unit through

panel cutout. Tighten

pawl screws (x2)

Step 5: Peel adhesive backing, align pins on

rear of cover plate into holes on

mounting plate and press firmly

1.550±0.010

1.600±0.025

R.125

Figure 3.6

Front Mount Installation

Step 1: install

grommets

Step 2: place screw through

mounting plate and

into pawl latch (x2)

Step 3: attach mounting

plate to unit

Step 2: attach unit to panel

with screws (x2)

Step 1: install

grommets

Step 3: place adhesive (x2) on panel in

locations shown, and peel backing

off adhesive

Step 4: align pins on rear of cover plate into

holes in panel and press firmly.

Figure 3.7

Rear Mount Installation with Cover

Panel Cutout Detail

Panel Cutout Detail

Summary of Contents for TA102

Page 1: ...Revision K May 14 2020 ...