1-6

Aggregate Correction Factors

The oven stores up to twenty user-defined

aggregate correction

factors

(

ACFs

), which are percentage values used to adjust the

measured asphalt content for specific aggregates.

Measurement Displays

During a burn cycle, the oven displays measurement units of

percent loss

(

%Loss

). The

%Loss

measurement is the difference

between the sample weights before and after the burn cycle,

expressed as a percentage of the starting mass.

Two Burn Modes

The oven offers two

burn modes

. The burn time can be set

manually by the operator (

Program Time

mode), or it can be

adjusted automatically by the oven (

Auto-Control

mode). In

Auto-Control

mode, the oven limits the burn time according to

the

cutoff limit

specified by the operator. The cutoff limit can be

defined in grams or as a percentage.

The oven can store data for up to 200 HMA samples. Sample

data is stored in

project

files created by the operator. Up to

twenty project files can be defined. Sample data is stored in the

active project file, either manually using identification numbers

entered by the operator, or automatically using the

Auto-Store

function.

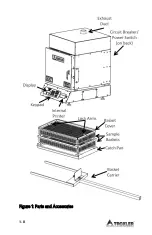

PARTS AND ACCESSORIES

Figure 1 shows the ICO and its accessories. Use this figure to

locate and identify the following parts:

1.

The

oven

contains the electronics and heating elements

to burn the asphalt binder from the aggregate. The oven

includes an

internal printer

used to print sample data

and system status information. An

integrated scale

(not

shown) monitors mass loss throughout the burn cycle.

The oven’s

exhaust duct

vents fumes produced during

the ignition to a suitable ventilation system.

Summary of Contents for ICO 4740

Page 2: ......

Page 13: ...ICO xi Figure 21 Disengage Paper Spindle A 10 Figure 22 Insert New Paper Roll A 11...

Page 14: ......

Page 22: ...1 8 Figure 1 Parts and Accessories...

Page 138: ......

Page 152: ......

Page 161: ...ICO C 1 Appendix C SPECIFICATIONS This appendix contains specifications for the ICO...

Page 166: ......

Page 170: ......