EN

9

digital soldering station PSIS 10-230V

Start-up

Unpacking the device

•

Take the device and the accessories out of the packaging.

•

Check the contents for completeness and look for

damages.

Warning

Risk of suffocation!

Do not leave the packaging lying around. Children may

use it as a dangerous toy.

•

Dispose of the packaging material according to the

national regulations.

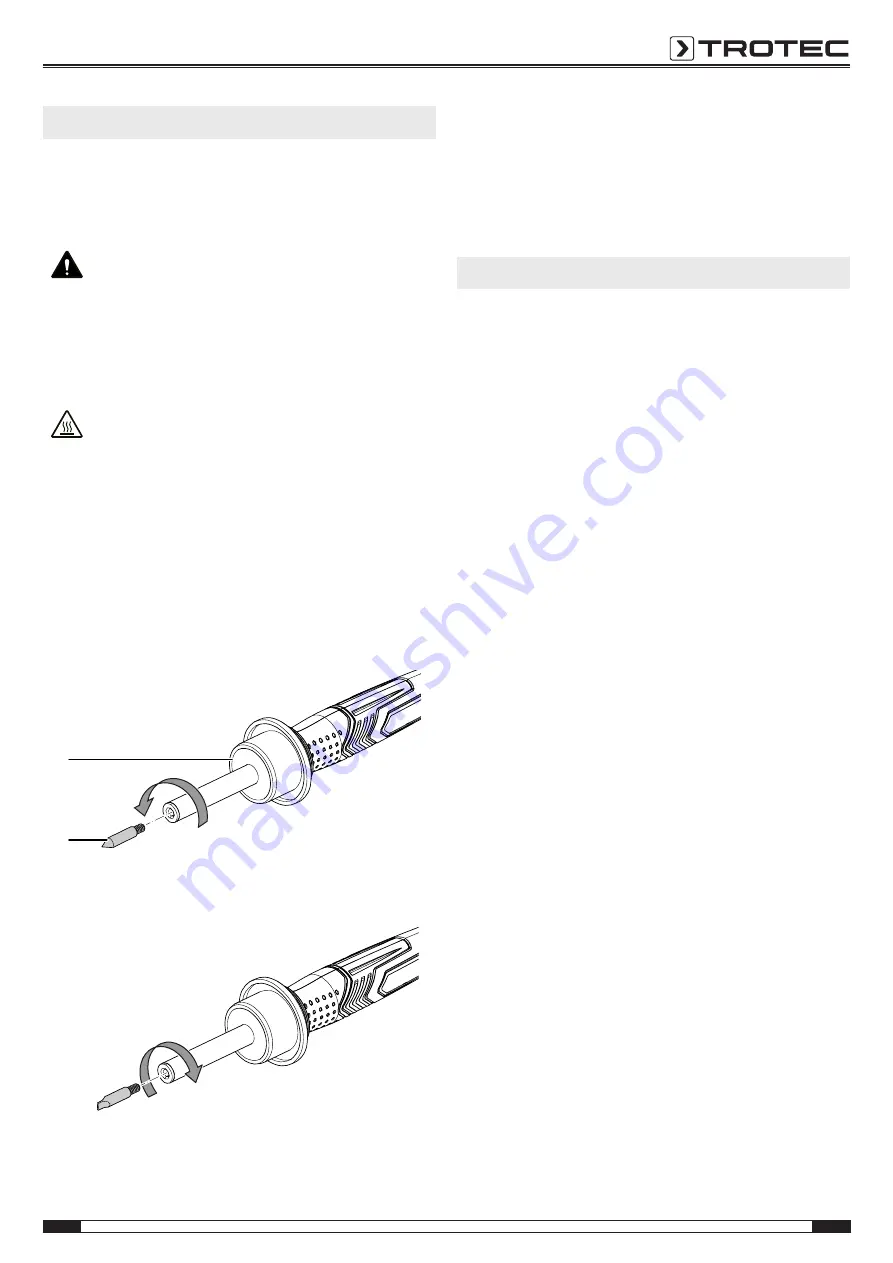

Inserting / changing the soldering tip

Caution

Burn hazard!

Removing the soldering tap must only be

performed if the device has been switched off and the

soldering tip has cooled down.

The soldering tip (

8

) has a screw thread which allows to quickly

and easily replace the soldering tip.

1. Hold onto the mains plug while pulling the power cable out

of the mains socket.

2. If necessary, allow the soldering iron (

9

) to cool down in

the soldering iron holder (

4

).

3. Turn the pre-mounted soldering tip (

8

) counter-clockwise

in order to unscrew it from the soldering iron (

9

).

9

8

4. Turn the new soldering tip (

8

) clockwise into the soldering

iron (

9

).

Tin-coating the soldering tip

Prior to initial start-up of the soldering station or if using a new

soldering tip, the soldering tip (

8

) must be coated with tin.

Connecting the power cable

1. Insert the mains plug into a properly secured mains

socket.

Operation

General information:

•

The parts to be soldered must be clean and must not show

any signs of an oxide layer. If required, remove any oxide

deposits with alcohol or steel wool.

•

Use a suitable mat to protect the working surface from

splashes resulting from soldering.

•

Avoid vibrations on the workpiece during the cooling

phase. This can lead to 'cold solder joints'.

•

Prior to starting soldering work, use some solder to tin-

coat the clean soldering tip.

•

Do not use the maximum temperature longer than

absolutely necessary. This will increase the working life of

your soldering tip.

•

Once the solder starts melting on the soldering tip, the

required temperature has been reached. If clots begin to

form, the temperature is too low.

•

If the soldering tip does no longer work properly, try

cleaning it using fine sand paper. Afterwards, tin-coat the

soldering tip again by applying some solder and soldering

flux around the tip, then heat the tip.