4. There are several Size Marks (3) on the

Bypass Feeder Table.

Align the edge of cut sheet paper with the

Size Marks (3), and insert the cut sheet

into the Bypass until it touches the feeding

roller.

Cut sheet paper is transported in a little, and then

awaits the original to be inserted.

Chapter 2 Basic Operation

2-17

NOTE

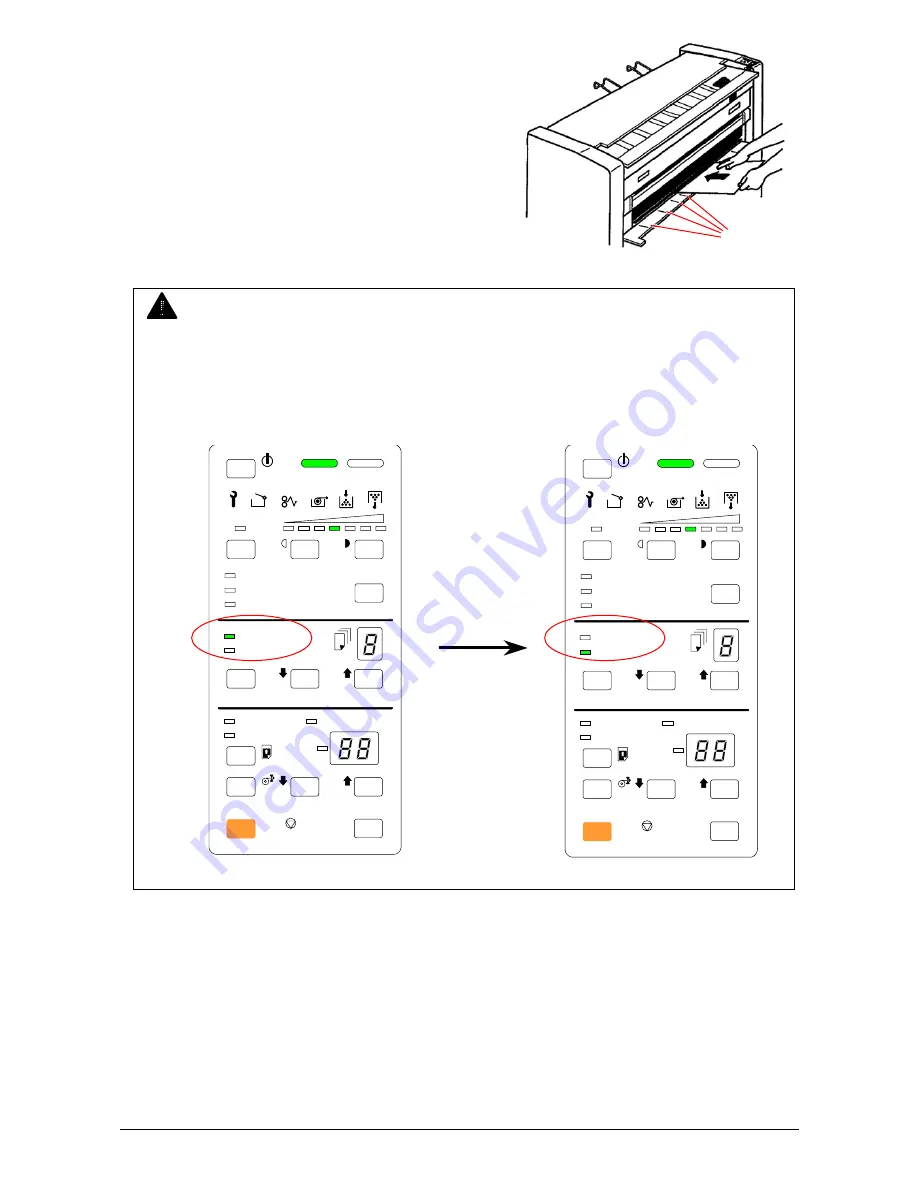

Normally the Roll Paper Feeding Mode is selected.

But if only you set the cut sheet paper the Cut Sheet Paper Feeding Mode is automatically

selected.

(The CUT SHEET Indicator on the Operation Panel automatically lights instead of ROLL

Indicator at this time.)

<Roll Paper Mode> <Cut Sheet Paper Mode>

ROLL

CUT SHEET

STAND BY

SL

LIGHTER

DARKER

FILM

VELLUM/TRACING

PLAIN PAPER

MEDIA

C

CLEAR

DECREASE

INCREASE

LEAD EDGE

TRAIL EDGE

CUT MODE

DECREASE

INCREASE

C

CLEAR

STOP

ALL CLEAR

ROLL

CUT SHEET

STAND BY

SL

LIGHTER

DARKER

FILM

VELLUM/TRACING

PLAIN PAPER

MEDIA

C

CLEAR

DECREASE

INCREASE

LEAD EDGE

TRAIL EDGE

CUT MODE

DECREASE

INCREASE

C

CLEAR

STOP

ALL CLEAR

3