TMCM-343 Hardware Manual (V1.07 / 2011-JUN-08)

13

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

7.1.3

TMC428 motion controller

The TMC428 is a high-performance stepper motor control IC and can control up to three 2-phase-

stepper-motors. Motion parameters like speed or acceleration are sent to the TMC428 via SPI by the

microcontroller. Calculation of ramps and speed profiles are done internally by hardware based on the

target motion parameters.

7.1.4

Stepper motor drivers

On the TMCM-343 modules the TMCM246 chips are used. These chips have the stallGuard™ feature.

As the power dissipation of TMC246 chips is very low no heat sink or cooling fan is needed. The

temperature of the chips does not get high. The coils will be switched off automatically when the

temperature or the current exceeds the limits and automatically switched on again when the values

are within the limits again.

The TMCM-343 module is equipped with a circuit that extends the microstep resolution of the TMC246

chips to true 64 times microstepping. The maximum peak coil current of each stepper motor driver

chip is 1500mA.

7.2

Power supply

Two different power supplies have to be provided for the TMCM-343: +5VDC for the module

functionality and +7… 34VDC for the motor supply. Please use all listed pins for the power supply

inputs and ground parallel.

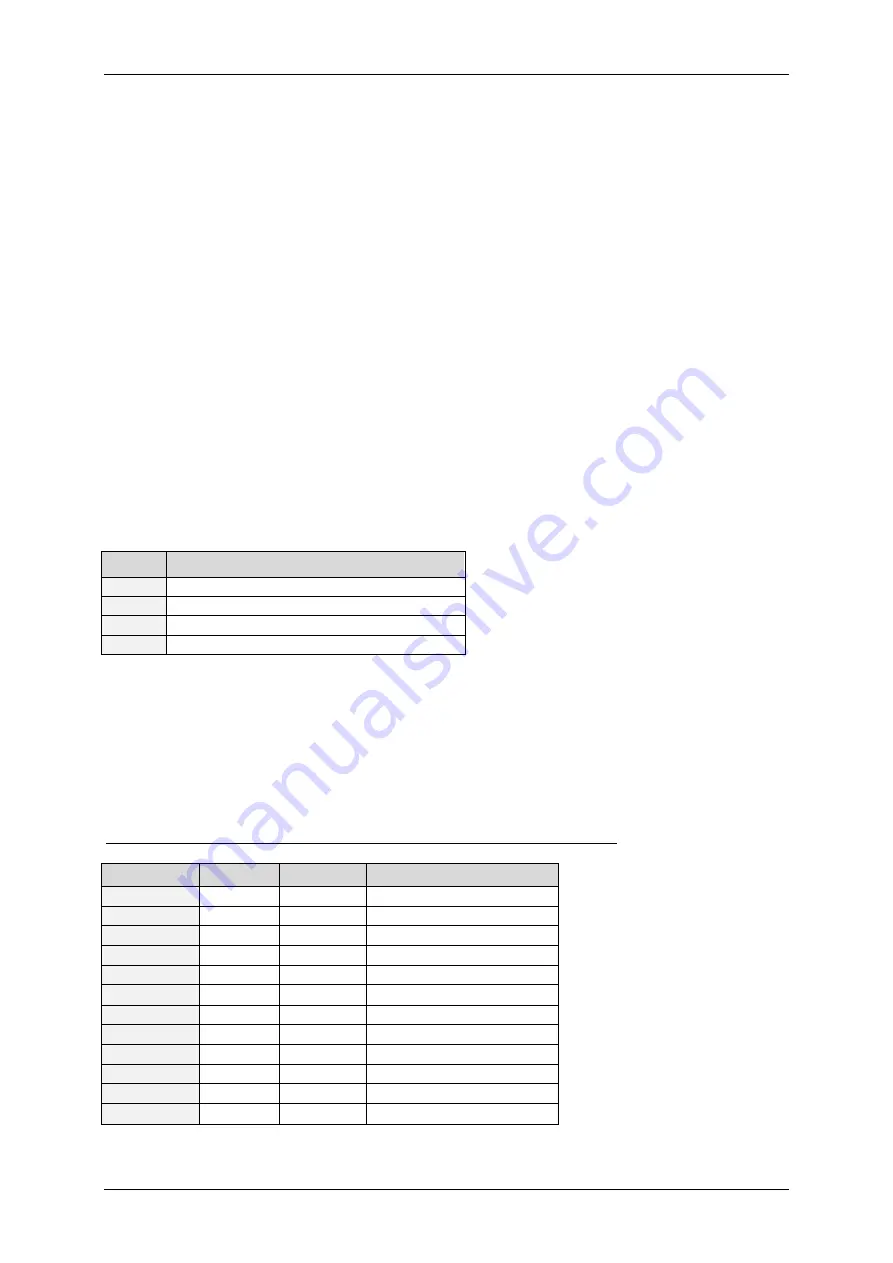

Pin

Function

1, 3

+5V DC (+/- 5%), I

max

= 50mA power supply

2, 4

Ground

5, 7, 9

+7… 34V DC motor power supply

6, 8, 10 Ground

Table 7.1: Pinning of power supply

7.3

Motor connection

Never connect or disconnect the motors while the TMCM-343 Module is switched on. Doing this

will destroy the driver ICs!

The TMCM-343 controls up to three 2-phase stepper motors.

Table 7.2 shows how to connect the three motors with the 68-pin connector:

Pin Number Direction

Name

Motor Numbers and Coils

20

out

Motor0_A0

Motor #0, Coil A0

22

out

Motor0_A1

Motor #0, Coil A1

24

out

Motor0_B0

Motor #0, Coil B0

26

out

Motor0_B1

Motor #0, Coil B1

28

out

Motor1_A0

Motor #1, Coil A0

30

out

Motor1_A1

Motor #1, Coil A1

32

out

Motor1_B0

Motor #1, Coil B0

34

out

Motor1_B1

Motor #1, Coil B1

36

out

Motor2_A0

Motor #2, Coil A0

38

out

Motor2_A1

Motor #2, Coil A1

40

out

Motor2_B0

Motor #2, Coil B0

42

out

Motor2_B1

Motor #2, Coil B1

Table 7.2: Pinout for motor connections