User's Manual Rev B / February 2021 / M125 Helium Compressor

97-00020-000

5

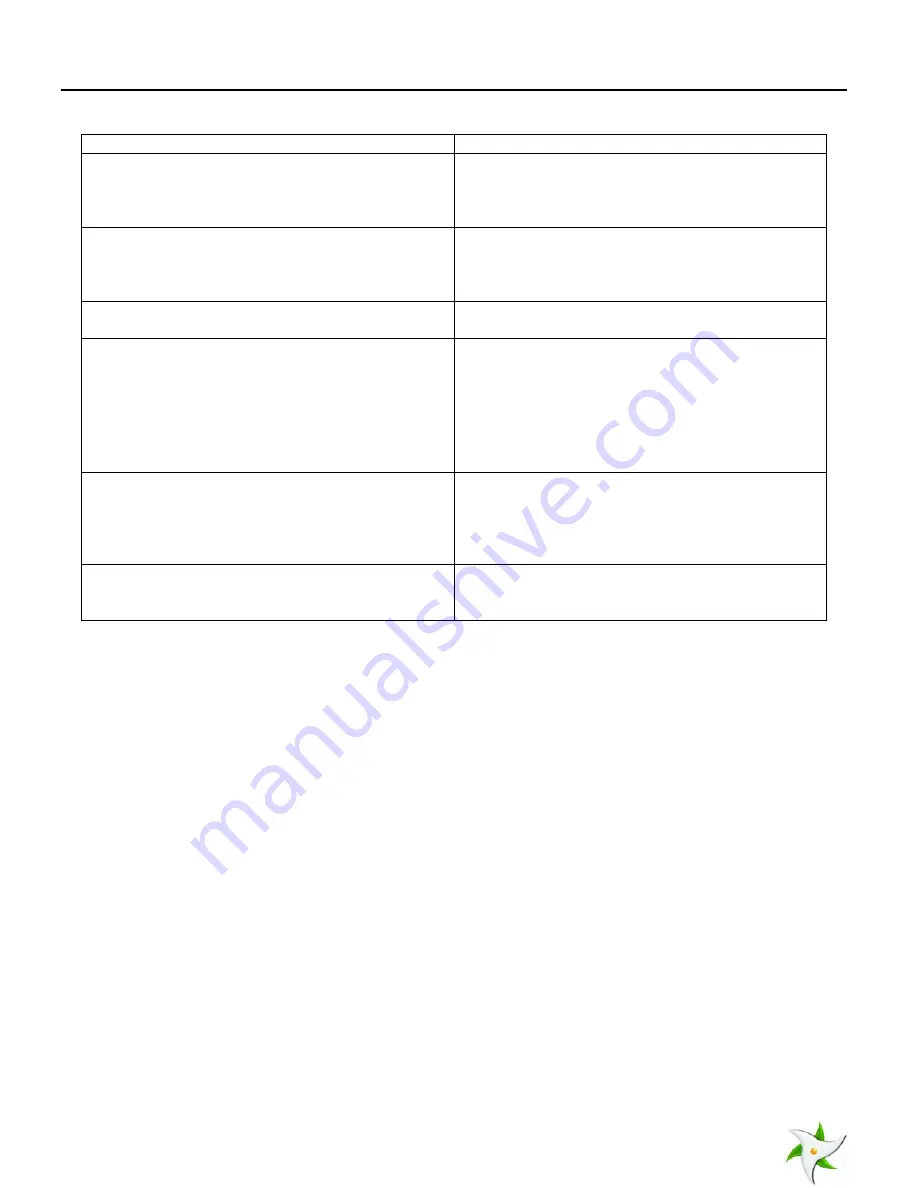

Table 4-1: Model M125 Helium Compressor Subsystems

Subsystem Name

Function

Thermal switch (TS1)

Purpose:

Monitors helium temperature upstream of the

heat exchanger

Safety Function:

Will turn OFF the compressor if the

temperature gets too high

Thermal switch (TS2)

Purpose:

Monitors helium temperature downstream of the

heat exchanger

Safety Function:

Will turn OFF the compressor if the

temperature gets too high

Unloading valve

Purpose and Safety Function:

Equalizes pressure within the

compressor upon power interruption

Fuses:

•

Fuses for the main input power

•

Fuses for cold head drive circuit

•

Fuses for the 24V control circuit

•

Fuses for the cold head heater circuit

•

Fuses for the fan motor (air cooled only)

•

Fuses for the oil pump motor (air cooled only)

Safety Function:

Over current protection

Internal relief valve

Purpose:

Opens a shunt between the high and low-

pressure helium gas circuits

Safety Function:

If the differential pressure exceeds a

preset value, this valve opens to allow safe operation

External relief valve

Purpose and Safety Function:

Opens the helium gas circuit

to atmosphere if the helium gas pressure exceeds 350 PSI

(24.1 Bar)

4.1.4

Operational Flow

The workflow of helium gas within the compressor follows these steps:

1.

High-pressure helium gas is delivered from the compressor to the cold head through the "Supply" helium flex

line at 250-260 PSI (17.24 – 17.93 Bar).

2.

The helium gas is then compressed during the compression stroke of the cryopump.

3.

The cryopump then expands the helium gas to expand during its expansion stroke. During this cycle of

compression and expansion of the cryopump, the helium gas is forced through regeneration materials to

increase the thermodynamic efficiency of the cycle.

4.

With each successive cycle, the regeneration material becomes colder and colder.

5.

Eventually, the cryopump temperatures come down to cryogenic range.

6.

After expansion, the helium gas returns to the compressor through the "Return" helium flex line at 50-100 PSI

(3.45 – 6.90 Bar) to begin the cycle again.

The helium flow between the Model 125 compressor’s components is illustrated in

and

, for the water-cooled and air-cooled version of the Model 125 compressor, respectively.