8

SELECTING PROPER DIES

Proper die selection is essential. Other than the obvious

necessity of matching shaped punches and dies, there are

two other basic selection factors that must be considered.

The first is die clearance. Different material types and

different material thicknesses require different clearances

between the punch and die. In order to maintain the best

possible hole while remaining within the tonnage

capacity of the machine, it is essential to choose the die

with the proper clearance. The second is the die angle.

Most structural shapes can be punched with the standard

flat dies, but "I" -beams and most channels which

have a 2-in-12 taper require the use of special

9-1/2 degree angled dies. Car and ship channel

flanges and other structural shapes with a 2 degree

taper can be punched with flat dies. Materials with

a flange taper of less than 5 degrees can also be

punched with the flat die, however, the hole will be

slightly angled. Refer to specific information and

tables within this manual for the proper punch and

die combination.

Hougen-Ogura Punches are

designed to be used in

Structural Steel. If used in harder

or higher tensile strength

materials, performance will be

impeded and serious damaged

could occur to your unit.

Your Hougen-Ogura punch unit

has been equipped with a new

die configuration. Please review

this information prior to

operating your machine

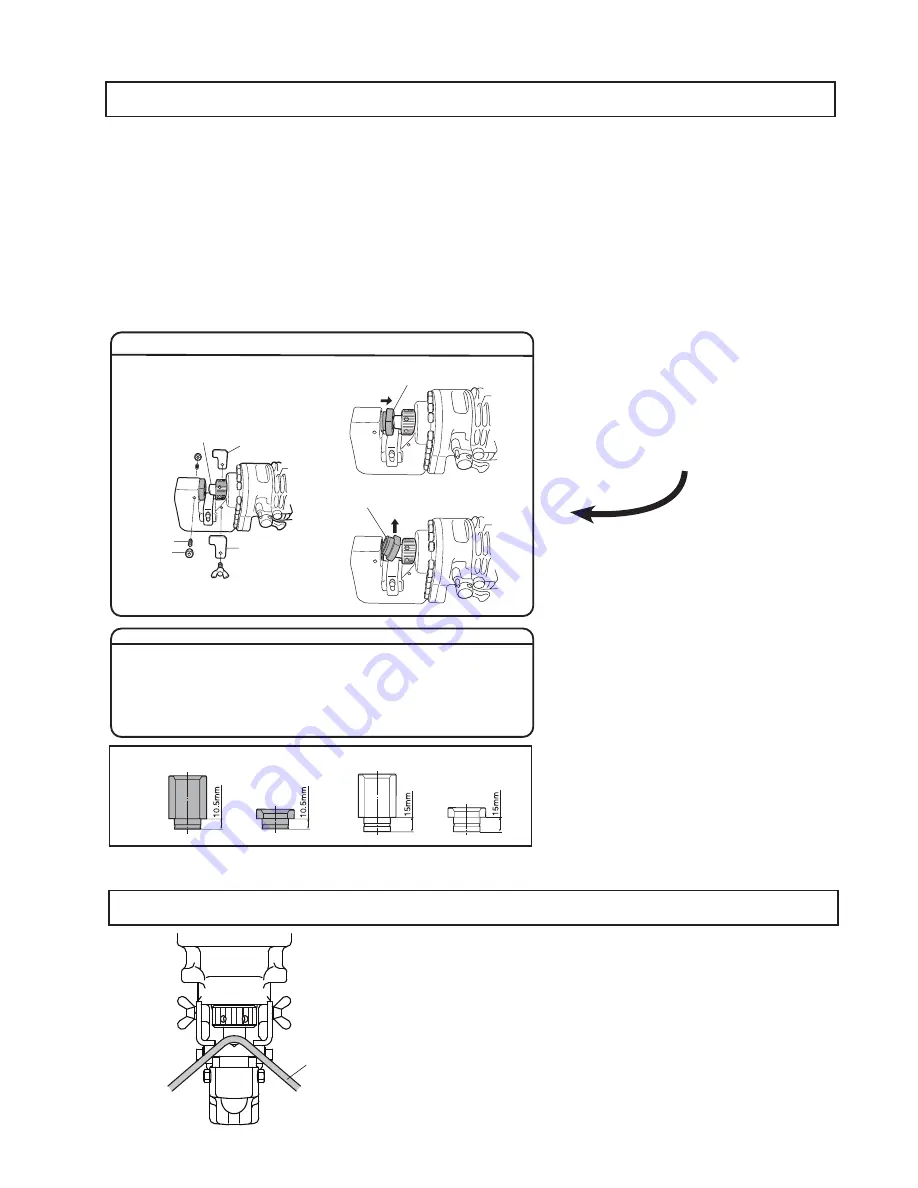

1. To make it easier, please remove the

strippers

3. Pull the die up to the tip of the punch

2. Unscrew the nuts and set screws

that hold the die in place

4. Remove the die from the “C”- frame,

inclining it to remove.

STRIPPER

STRIPPER

PUNCH

SET SCREW

NUT

REMOVING THE NEW DIE

INSTALLING A PUNCH

1. To make the operation easier, first remove the strippers on both sides.

2. Reference your Operators manual and remove your punch and the die.

3. Install a new punch and punch retaining nut.

4. Install the die (Reference the steps above and work in reverse)

5. Tighten the punch retaining nut according to the Instructions in your Operators manual.

New Die

Old Die

CAUTION WHEN SELECTING THE DIE

It is important that the die selected is correct for the thickness of the material to

be punched.

Punching material of thickness 4 mm to 8 mm using a die for thinner material

can cause the punch to jam in the material. This is due to the smaller clearance

betweenthe die and punch. In such a case the material will be pulled up by the

retracting punch as shown in the drawing on the left. Special care should be

taken when punching flat bar of mild steel, aluminum and copper.

Material

Summary of Contents for Hougen-Ogura PUNCH PRO 75004PR

Page 12: ...12 PARTS BREAKDOWN ...