13

Model 201BA BEVELMASTER

TM

92-0631 : Orig. 960119

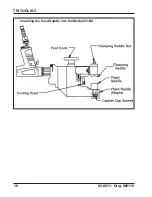

Retract the Cutting Head by rotating the Feed Knob.

The pipe or tube to be end prepped may now be set into the Adjustable Saddle.

The Clamping Saddle Nut is turned, lowering the Clamping Saddle down onto the

pipe or tube.

Pipe Position when seated between the Saddles

Tool Bit to pipe clearance

Continue this operation until the pipe or tube is clamped securely between the

Adjustable Saddle and the Clamping saddle.

Verify a clearance of 1/8” (3.2 mm) minimum between the Tool Bit and the pipe or

tube face.