PIVOT FRAME JIG

-14-

workpieces (eg. rustic nameplates).

A particular advantage of the ‘open’ construction

of the pivot frame, is the ability to see the

workpiece clearly, with the router assembly riding

well above the workpiece. This can be of

particular advantage for work against a template,

where the cut needs to be ‘stopped’ by visual

inspection.

Guided Planing Mode

This machining mode is essentially an extension

of the foregoing arrangement and permits

planing of long work, together with a facility for

machining parallel grooves or edge-mouldings.

It requires a flat work surface and two straight-

edged battens of constant thickness, which may

be fixed to a flat work surface (cramping is quite

suitable), such that the straight edges are

separated by a fixed distance and are parallel.

The jig is adjusted so that the flanges of the

nylon shoes ride on the battens and the smaller

diameter of the shoes bears against the edges

of the battens. Ride-height is determined initially

by the depth of the battens, but may be modified

by suitable arrangement of the shoe spacers.

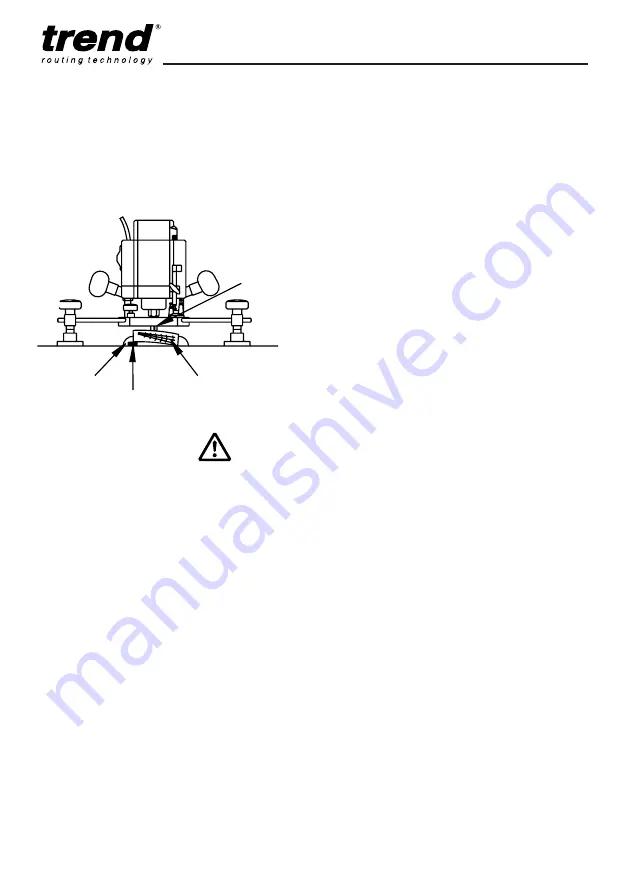

The workpiece may be attached to the worktop

by fillets of hot-melt glue. Where the workpiece

is uneven on both surfaces (e.g. it may be

twisted), it may be packed with small pieces of

veneer at the high spots, until it cannot be

rocked on the worktop; the glue fillets may then

be applied.

It is recommended that the largest diameter

bottom-cut router cutter available is used for this

operation. The use of routers limited to 1/4"

diameter shanks will reduce the possibilities but,

for example, a 25.4mm (1") diameter cut will be

obtained from straight two-flute cutter Trend Ref.

4/08X1/4TC and a 30mm cut from scribing ovolo

cutter Trend Ref. 6/5X1/4TC, both available with

1/4" shank.

To begin, the jig should be moved over the work

with the cutter stationary, in order to find the

highest point; depth of cut may then be set with

reference to this point. It is recommended that

several passes are made over the work with a

very small depth of cut (no greater than 0.5mm),

gradually clearing the high-spots and eventually

arriving at a flat smooth surface.

The router may be left to slide freely on its rods

and guided by means of its plunge knobs for this

operation, since it will stay in place at any set

position, provided the cut is light. If the cut is too

deep, the router may take control and pull itself

across the work off-line.

For the final cut in particular, which should be no

greater than 0.2mm, the router should be locked

on the rods for each pass, and moved across

the work by means of the locking knobs on a

pivot bar and not by the handles on the router

itself. This will eliminate any tendency for over-

depth cutting due to hand-pressure ‘springing’

the guide rods.

Another possibility with the system is that of

machining straight parallel grooves, either

continuous or stopped, with any of a number of

straight or profiling cutters.

It is not wise to rely on accurate tracking of the

system along both parallel battens for work of

this nature, where positional accuracy of the

router is of importance. The work is better

carried out by preferential pressure on one

batten only.

Moreover, it is perfectly possible for even a stout

batten to spring slightly in the centre under

pressure, if it is cramped at the ends only. An

additional cramp or two towards the centre will

CUTTER

FLAT-BOTTOMED

STOCK

WARPED

PACKING

VENEER

FILLET

GLUE

Summary of Contents for PFJ/SET/1

Page 1: ...PIVOT FRAME JIG...