-26-

CRT MK2

EXAMPLE APPLICATION

Producing a Shield

■

Construct an actual size template of the

design from 6mm MDF or plywood ensuring

that it is accurate and free from

imperfections.

■

Fix the template to the back of the workpiece

to be used using screws or double sided

tape.

■

Rough cut the workpiece to the shape of the

template using a band saw or jigsaw leaving

2-3mm oversize.

■

Fit a ball bearing guided trimmer cutter.

■

Lay the workpiece (with template fitted) face

down on the table surface. Adjust the height

of the cutter. Ensure that the ball bearing will

contact the template and the cutting edge of

the cutter will machine the full edge of the

workpiece.

■

Fit the profiling top guard and adjust height to

give a 6mm gap between the top of cutter

and underside of template.

■

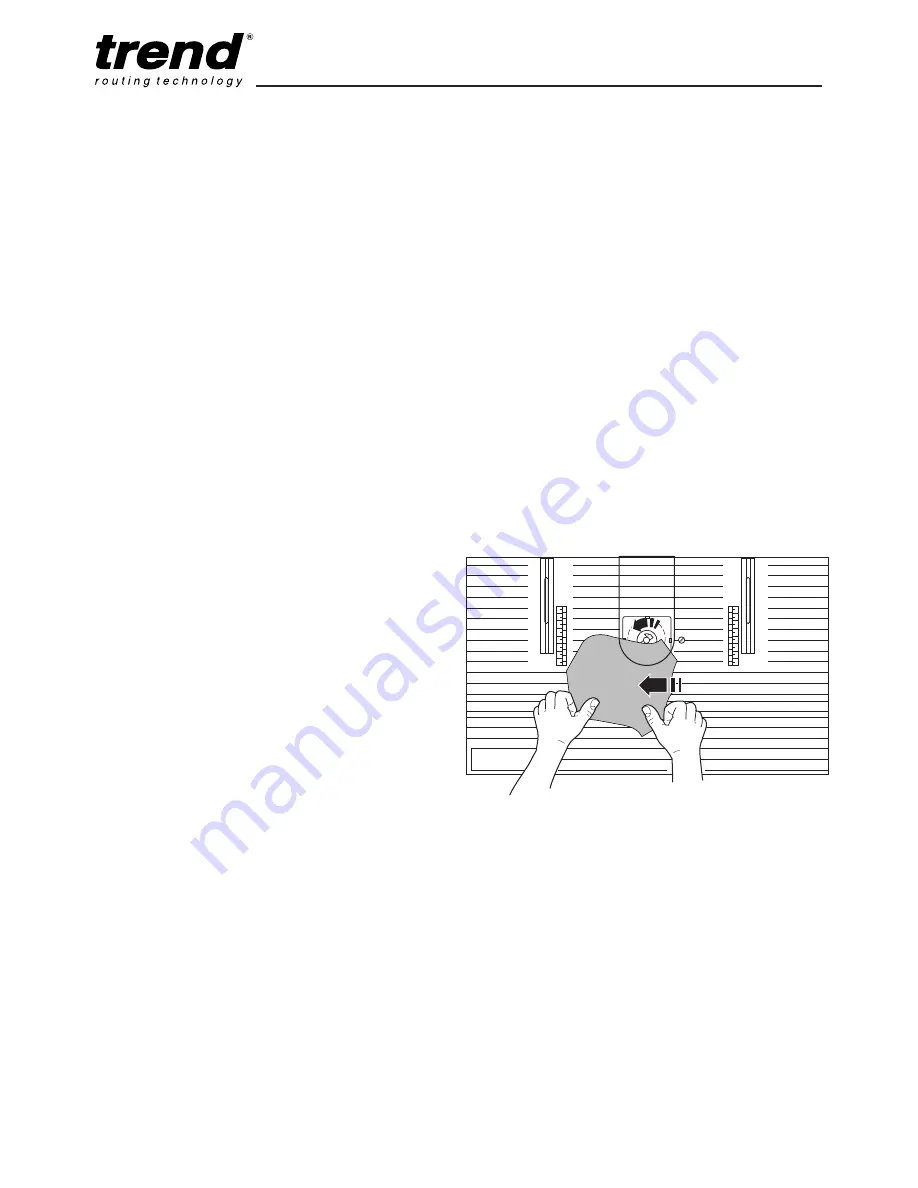

Switch router on and position the workpiece

against the lead-on pin as shown. The

workpiece should not contact the cutter.

■

Rout the shield using the procedure

described on the previous pages.

Useful advice

If natural woods are used, consideration should

be given to break-out of short grain which will

effect your decision as to where to start the

routing operation in order to prevent it.

Moulding the Shield

A suitable ball bearing guided cutter should be

chosen to mould the shield.

■

Fit chosen moulding cutter and adjust height

of cutter to achieve shape required.

■

If the full edge of the workpiece is to be

machined, leave the template attached to the

workpiece so as to provide a guide for the

ball bearing. Otherwise the template can be

removed, providing there is sufficient edge for

the ball bearing to follow.

■

Repeat the same routing procedure as

before.

If the profile required involves excessive removal

of material, it is advisable to take two passes

with the cutter. First reduce the height of the

cutter protruding from the table, this in effect,

reduces the amount of material which will be

removed, or fit a larger ball bearing, if one is

available for that particular cutter.

The second pass can then be made to give the

required finish.

Carrying out this two stage routing operation has

many advantages.

■

Improved finish on workpiece

■

Less load on cutter and router

■

Far less risk of workpiece snatching

Definition of Snatching

This can be described as the cutter catching the

workpiece and projecting it away from the

direction of rotation. The workpiece is often

taken from the operator's hands and projected

across the work area. It can have potentially

dangerous consequences if the cutter is

unguarded and/or the operator's hands are too

close to the cutter. Damage to the cutter can

also be caused.

The following precautions should be made to