MAINTENANCE

With the Plate removed the Cutter Drum will simply

slide off the Drive Shaft. The fitting of the drum is

basically the reverse of the removal procedure.

When changing cutter drums always check that the

flail shafts are not excessively worn with pronounced

grooves, also that the centres of the cutters and

spacers and check that the drum flail shaft location

holes are not elongated. The screws which hold the

drum end plates in position must be tight and in good

condition.

Note:

In general use it is expected that normally two

sets of flail shafts will be used to one set of TCT

cutters. While changing the drum the condition of the

drive shaft, the drum‟s hexagon drive, the drive shaft

bearings and side plate bearing should be checked.

If any roughness, side play or leakage of grease is

detected then new bearings should be fitted. Lightly

oiling the drive shaft will prevent a build up of rust,

which could cause difficulty when changing the drum

later. While the Drum is removed, check that the

vacuum port is free from blockages and that the

wear strip, which also retains the dust skirt are both

in good condition. Replace any damaged, worn or

suspect parts. Ensure that all the bolts are tight at all

times, recheck at regular intervals.

Cutter Replacement &

Configurations

Replacing cutters/spacers/flail shafts

Remove Drum; see

Changing Cutter Drums

.

Unscrew the four countersunk screws and locknuts

from either end of the Cutter Drum.

Using a suitable drift, push out each of the flail

shafts. Check each of the flail shafts for wear and

replace as required. Check also the Drum, Cutters

and Spacers for elongation and hole enlargement,

replace as necessary.

See the table below for the examples of the

sequence of spacers /cutters for each style of drum.

Before loading any cutters, establish which is

“Position 1”. (See next)

Position the two shorter rows to the left and at the

top as you look at the drum; identify the short row on

the left furthest away from you (at the “back” of the

drum), this is “Position 1”

For ease of assembly, mark the end of the drum to

help identify each flail shaft, rotate the drum away

from you marking each position in order. 1,2,3,4.

The drum’s web plate thickness and positions

can vary slightly; because of this, the quantity of

cutter and/or spacers may need to be adjusted,

ensure that the same amount of cutters and

spacers are fitted to opposite shaft to keep the

drum balanced. These examples are for

illustrative purposes only.

Method as per Single Web Drum;

Insert a flail shaft into the drum from the left side, in

position 1, so that its end is in the middle of the short

row, start to load with a single spacer first, fit the 9

cutters alternating with a spacer until the last cutter,

pushing the fail shaft further through as the shaft fills,

in this case end the short row with 1 single spacer.

Continue with the long row on the same shaft, but no

spacer is fitted before or after the last cutter (See

example below)

Rotate the drum away from you to complete shaft

2,3 and 4.

Finally secure the end plates with the four

countersunk screws and four new locknuts.

Example

for Position 1: - (Short Row) 1 x spacer,

followed by 9 x cutters and with a single spacer after

each cutter, but ending with a single spacer after the

last cutter. Continue with the long row, no spacer,

followed with 12 x cutters with a single spacer after

each cutter, ending with no spacer after the last

cutter.

Milling Cutter Single Web Drum (Economy load)

Example for Position 1: - (Short Row) 4 x spacers, followed by 1 x cutter, then 6 x spacers, followed by 1 x cutter, ending with 5 x

spacers, continue with the long row, 4 x spacers followed with 1 x cutter, then 8 x spacers followed by 1 x cutter ending with 9 x

spacers.

TCT CUTTERS FITTED TO SINGLE WEB DRUM

Position

Short Row

Left

Centre

Web

Long Row

1

1sp-9c-1sp

0sp-12c-0sp

2

2sp-9c-0sp

1sp-11c-2sp

Long Row

Right

Centre

Web

Short Row

3

0sp-12c-0sp

1sp-9c-1sp

4

2sp-11c-1sp

0sp-9c-2sp

TCT CUTTERS FITTED TO DOUBLE WEB DRUM

Position

Left Row

Left

Web

Middle Row

Right

Web

Long Right Row

1

0sp-6c-0sp

0sp-6c-0sp

0sp-8c-1sp

2

2sp-5c-1sp

1sp-5c-2sp

1sp-8c-0sp

Long Left Row

Left

Web

Middle Row

Right

Web

Right Row

3

1sp-8c-0sp

0sp-6c-0sp

0sp-6c-0sp

4

0sp-8c-1sp

2sp-5c-1sp

1sp-5c-2sp

MILLING CUTTERS FITTED TO SINGLE WEB DRUM (Standard load)

Position

Short Row

Left

Centre

Web

Long Row

1

1sp-1c-1sp-1c-2sp-1c-1sp

1sp-1c-3sp-1c-3sp-1c-6sp

2

1sp-1c-2sp-1c-1sp-1c-1sp

6sp-1c-3sp-1c-3sp-1c-1sp

Long Row

Right

Centre

Web

Short Row

3

6sp-1c-3sp-1c-3sp-1c-1sp

1sp-1c-2sp-1c-1sp-1c-1sp

4

1sp-1c-3sp-1c-3sp-1c-6sp

1sp-1c-1sp-1c-2sp-1c-1sp

Milling Cutter Single Web Drum (Full load)

Example for Position 1: - (Short Row) 3 x full milling cutters, followed by 1 x ½ size milling cutter, continue with the long row, 4 x full

milling cutters, followed by 1 x ½ size milling cutter.

MILLING CUTTERS FITTED TO SINGLE WEB DRUM (Full load)

Position

Short Row

Left

Centre

Web

Long Row

1

0sp-3c-½c-0sp

0sp-4c-½c-0sp

2

0sp-½c-3c-0sp

0sp-½c-4c-0sp

Long Row

Right

Centre

Web

Short Row

3

0sp-½c-c4-0sp

0sp-½c-3c-0sp

4

0sp-4c-½c-0sp

0sp-3c-½c-0sp

Milling Cutter Double Web Drum

Example for Position 1: - (Left Row) 6 x spacers, followed by 1 x full cutter, ending with 6 x spacers, continue with the (Middle

Row), no x spacer, followed by 1 x full cutter, then 3 x spacers, then 1 x full cutter ending with no spacers, continue with the (Long

Right Row), 3 x spacers, followed by 1 x full cutter, then 1 x half cutter, followed by 1 x full cutter, finishing with no spacer.

MILLING CUTTERS FITTED TO DOUBLE WEB DRUM

Position

Left Row

Left

Web

Middle Row

Right

Web

Long Right Row

1

6sp-1c-6sp

0sp-1c-3sp-1c-0sp

3sp-1c-½c-1c-0sp

2

0sp-1c-3sp-1c-0sp

1sp-1c-1sp-1c-1sp

0sp-1c-½c-1c-3sp

Long Left Row

Left

Web

Middle Row

Right

Web

Right Row

3

0sp-1c-½c-1c-3sp

0sp-1c-3sp-1c-0sp

6sp-1c-6sp

4

3sp-1c-½c-1c-0sp

1sp-1c-1sp-1c-1sp

0sp-1c-3sp-1c-0sp

The drum’s web plate positions may vary slightly; because of this the quantity of cutter and spacers may need to be

adjusted, these examples are for illustrative purposes only.

CUTTERS & SPACER QUANTITIES FITTED TO SINGLE WEB DRUM

CUTTER TYPE

PART No

CUTTERS

SPACERS

TCT

320.5500

82

88

Beam

320.5120

272

0

Star

320.3658

208

0

Milling (Economy)

320.5600

16

144

Milling (Standard)

320.5600

24

72

Milling (Full load)

320.5600 / 320.5650

28 full / 8 half

0

Spacer

320.4140

CUTTERS & SPACER QUANTITIES FITTED TO DOUBLE WEB DRUM

CUTTER TYPE

PART No

CUTTERS

SPACERS

TCT

320.5500

76

80

Beam

320.5120

268

0

Star

320.3658

204

0

Milling (Full load)

320.5600

22 full / 4 half

54

WIRE BRUSH QUANTITIES FITTED TO BRUSH HOLDER

Wire Brush

Spacers

Crimped Wire Brush

16

16

Twisted Wire Brush

23

23

MILLING CUTTERS FITTED TO SINGLE WEB DRUM (Economy load)

Position

Short Row

Left

Centre

Web

Long Row

1

4sp-1c-6sp-1c-5sp

4sp-1c-8sp-1c-9sp

2

1c-15sp-1c

1c-6sp-1c-15sp

Long Row

Right

Centre

Web

Short Row

3

9sp-1c-8sp-1c-4sp

5sp-1c-6sp-1c-4sp

4

15sp-1c-6sp-1c

1c-15sp-1c

Milling Cutter Single Web Drum (Standard load)

Example for Position 1: - (Short Row) 1 x spacers, followed by 1 x cutter, then 1 x spacers, 1 x cutter, 2 x spacers, 1 x cutter,

ending with 1 x spacer. Continue with the long row, 1 x spacers, 1 x cutter, then 3 x spacers, 1 x cutter, 3 x spacers, 1 x cutter,

ending with 6 x spacers.

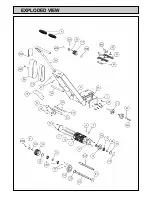

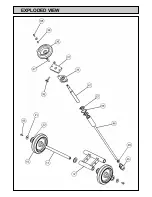

Summary of Contents for TFP200

Page 1: ...TFP200 FLOOR PLANER OPERATION MAINTENANCE ...

Page 6: ...EXPLODED VIEW ...

Page 7: ...EXPLODED VIEW ...