Instruction manual TREJON OPTIMAL UPX plough (2010)

16

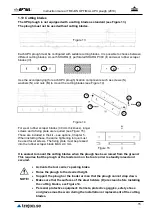

On the back of the plough body are springs (F) that are anchored in the steel holders (D).

This means that the cutting blades are sprung. The sprung cutting blades reduce damage

in the event of a collision.

The outer cutting blades (A) have a bent edge (not wear rubber) which reduces the risk of

becoming stuck in obstacles.

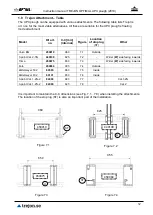

It is important to check wear and tear on the cutting blades daily. There are many factors that

affect this. These factors include ploughing speed, substrate, cutting angle, support plates and

adjustment of the floating mode. It is therefore important to maintain the distance

W

≥ 10 mm

between the lower edge of the cutting blades (1) and the lower edge of the steel holder (2)

(see Figure 16).

When the wear is significant and the distance

W

≤ 10 mm

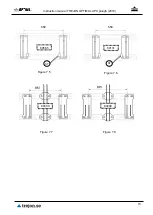

(see Figure 17), it is time to move all the

cutting blades downwards (see Figure 18). When this position is also worn, the cutting blades (B)

are turned or shifted (from left to right and vice versa); this applies to the cutting blades with bent

ends (A). It is important that the cutting blades do not protrude downwards more than 60 mm,

i.e.

W max. = 60 mm

.

NOTE!

Trejon Optimal cutting blades are made of the highest quality steel to provide a

low overall cost. The cutting blades are wear components and their service life

CANNOT be determined. The cutting blades are NOT covered by any warranty.

NOTE!

Damage due to the use of other cutting blades is NOT covered by any warranty.

NOTE!

Always replace cutting blades when they have become worn.

Figure 16

2

1

A

B

Figure 17

Figure 18

B

A

F

B

A

D