SS-SVX07B-E4

15

Installation

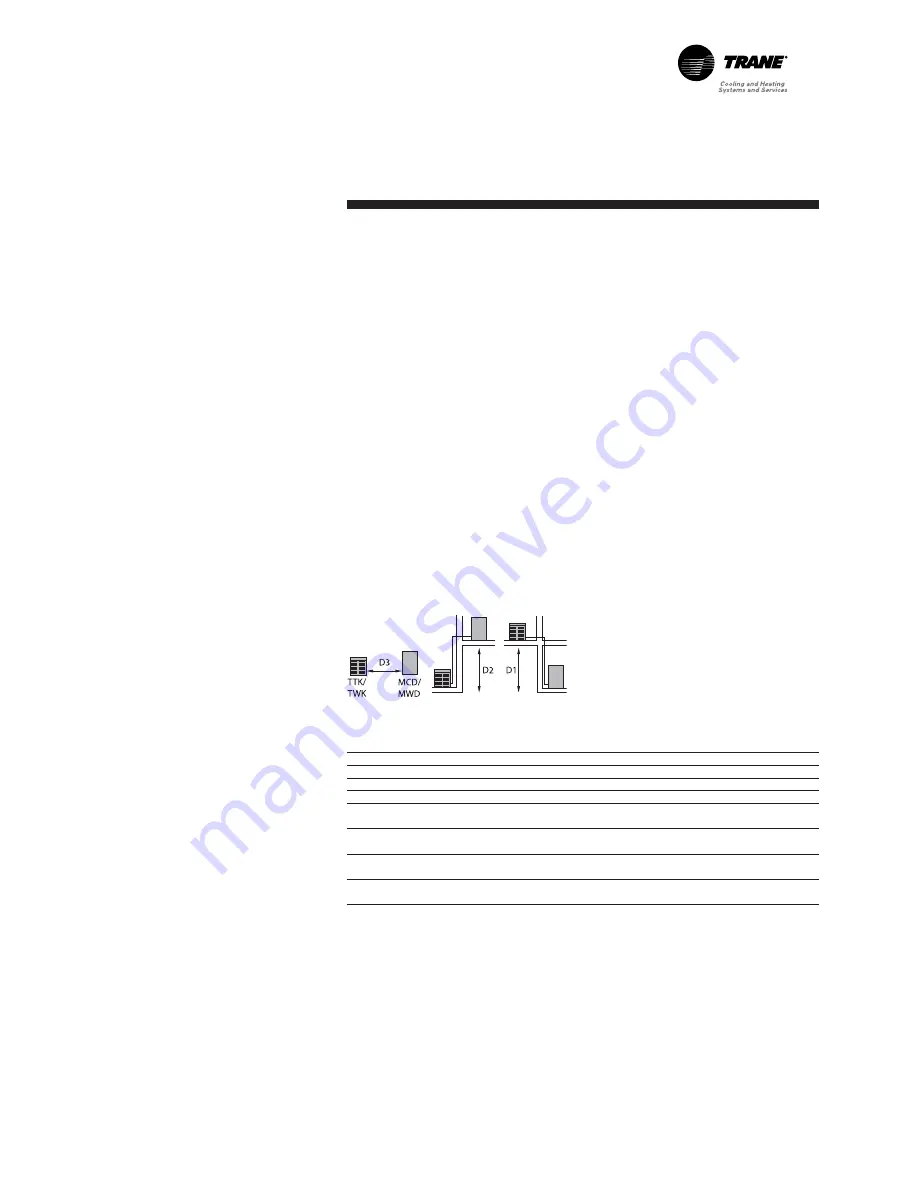

Table 10 - Recommended piping R407C/R22

D3

D2

D1

Line diameter (inches)

Outdoor unit

Indoor unit

(m)

(m)

(m)

Gas

Liquid

TTK/TWK 512

MCD/MWD 512

20

12

15

1/2

1/4

TTK/TWK 518

MCD/MWD 518

24

18

24

5/8

3/8

TTK/TWK 524

MCD/MWD 524

24

18

24

5/8

3/8

TTK/TWK 530

MCD/MWD 530

12

12

12

5/8

3/8

40

18

24

7/8

TTK/TWK 536

MCD/MWD 536

18

18

18

3/4

3/8

40

24

7/8

TTK/TWK 048

MCD/MWD 048

24

18

24

7/8

3/8

40

1 1/8

TTK/TWK 060

MCD/MWD 060

18

12

18

7/8

3/8

40

18

24

1 1/8

1/2

Choice of installation

position

To ensure correct installation, the

following points must be

considered.

- The ceiling must be strong enough

to support the weight of the unit.

- Choose a place where it will be

easy to comply with the

recommended clearances, taking

into account the additional space

required due to external

accessories.

- Take into consideration the drilling

of the holes in the walls to connect

the unit.

- Make sure the maximum distances

between the two units are not

exceeded. See Figure 3 and

Table 10.

Figure 3- Recommended clearances and

maximum lengths used between two

units

Preparing the ceiling and installing

the unit

Drill holes in the ceiling to fix the

threaded rods according to the

dimensions given the Dimensions

section. The angle brackets can also

be used to space the drill holes.

Access is necessary on the

refrigerant connection side to

facilitate installation, maintenance

and access to the cabinet.

Four 8 mm diameter threaded rods

must be securely fixed into the

ceiling. Introduce the other end of

the rods through the slots of the unit

suspension brackets. Position the

shock absorbers, add washers and

screw the nuts down until the unit is

correctly supported. The unit must

be perfectly level in both directions

to ensure correct evacuation of the

condensates. If there is enough

space, a rubber or neoprene sheet

can be placed between the ceiling

and the unit.

Summary of Contents for MCD 048

Page 27: ...SS SVX07B E4 27 Notes...