26

PVC

CEMENT

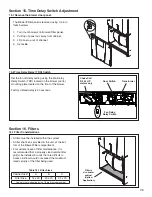

Section 12. Condensate Drain Piping

12.2 Connect Condensate Drain Piping

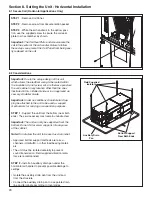

STEP 1 - Select the drain connections that are ori-

ented for your application.

STEP 2 - Prepare the condensate drain connections.

From the factory, the unit comes with plugs in both

•

upflow condensate drains and an additional plug in

the documentation packet.

For upflow applications, remove upflow condensate

•

plug(s) and connect condensate piping.

For all other applications, do not remove upflow

•

condensate plugs. Remove the cover from the

needed condensate drain connections and connect

condensate piping.

If the secondary drain connection is not used, close

•

secondary drain with plug from documentation

packet (all applications except for upflow).

Note:

Upflow and horizontal orientations require the

Coil panel to be removed in order to make the drain

connections.

Note:

Make certain that the unit has

been installed in a level position to allow for proper

draining.

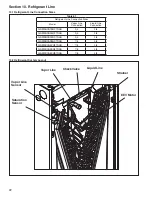

STEP 3 - Connect 3/4” PVC pipe to the primary drain

connection (and the secondary drain connection if

used) using threaded drain nipples.

Use Teflon tape on the air handler drain line con-

•

nections. Do not use pipe joint compound or PVC/

CPVC cement on drain nipple.

Hand tighten the drain pipe.

•

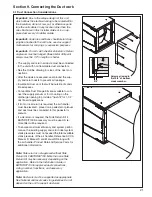

Horizontal Left

Condensate Drains

Upflow

Condensate

Drains

Downflow

Condensate

Drains

Horizontal Right

Condensate Drains

S

P

S

P

S

P

S

P

Drain Nipple

3/4” PVC pipe

Teflon Tape

PVC/CPVC Cement

12.1 Condensate Drain Piping Considerations

Condensate drain plumbing must comply with na-

•

tional, state, and local codes.

Route condensate drain lines away from air handler

•

so they do not interfere with access panels.

Slope the drain lines downward a minimum of 1/4”

•

per foot, support per local codes.

Do not use reducing fittings in the condensate drain

•

lines.

Do not connect the drain line to a closed drain

•

system.

Do not use a torch or flame near the plastic drain

•

pan coupling.

A P-trap is not required for proper drainage due to

•

the positive pressure of the air handler; however,

it is recommended to prevent efficiency loss of

conditioned air.