Page 12

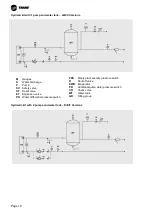

6. WATER CONNECTIONS

a.

EVAPORATOR

The connection tubes have to be supported adequately in order that their weight does not damage the plant.

It is necessary that the water flow rate to the unit is compatible with the evaporator one. It is also necessary that the water flow

rate is kept uniform while the unit is running: it is suggested to use always a pump system dedicated to the unit and independent

from the remaining part of the plant.

Before stalling units with temperature around 0°C please evacuate the exchanger with compressed air in order to avoid

breakings due to ice.

If the unit is installed in order to replace another, the entire hydraulic system must be emptied and cleaned before the

new unit is installed. Regular tests and proper chemical treatment of water are recommended before starting up the

new unit.

In the event that glycol is added to the hydraulic system as anti-freeze protection, pay attention to the fact that intake

pressure will be lower, the unit’s performance will be lower and water pressure drops will be greater. All unit-protection

methods, such as anti-freeze, and low-pressure protection will need to be reset. Before insulating water piping, check

that there are no leaks.

CAUTION:

Install a mechanical water filter at the water outlet of each heat exchanger. Failure to install the filter allows

access of solid particles and / or welding slag inside the heat exchanger. We recommend the installation of a filter having a

filtering net with holes not exceeding 0.5 mm in diameter.

Trane cannot be held responsible for any damage to heat exchangers due to the lack of good quality water filters.

Maximum operating pressure: 6 bar

Summary of Contents for FLEX HP HT

Page 2: ...Page 2 ...

Page 3: ......