5

Once you have identified a suitable antenna

mounting site, follow these steps to drill the

mounting holes and cable access hole to prepare

the site for installation.

a.

Unfold the supplied template and place it

onto the mounting surface. Make sure the

“FWD” (forward) arrow points toward the

bow and is parallel to the vessel’s centerline

NOTE:

You do not need to mount the antenna exactly

on the vessel’s centerline, but the antenna’s forward

arrow must be parallel to it.

b.

Use the template to mark the locations for the

four mounting holes.

c.

Drill a 5/16" (8 mm) hole at the four

mounting hole locations you marked in

Step b (see Figure 6). Later, you will insert

four 1/4"-20 bolts through these holes to

secure the antenna to the mounting surface.

d.

Mark a location for the cable access hole,

either in the center of the antenna mounting

hole pattern or in an area aft of the antenna.

Later, you will route the antenna cable

through this hole and into the vessel.

e.

Using a hole saw, drill the cable access hole in

the location you marked in Step d. Be sure to

size the hole appropriately to maintain a

cable bend radius of at least 3" (75 mm). If the

hole location is in the center of the antenna

mounting hole pattern, the diameter of the

cable access hole must not exceed 3.5"

(88 mm). Smooth the edges of the hole to

protect the cable.

f.

Clean and dry the antenna mounting surface.

g.

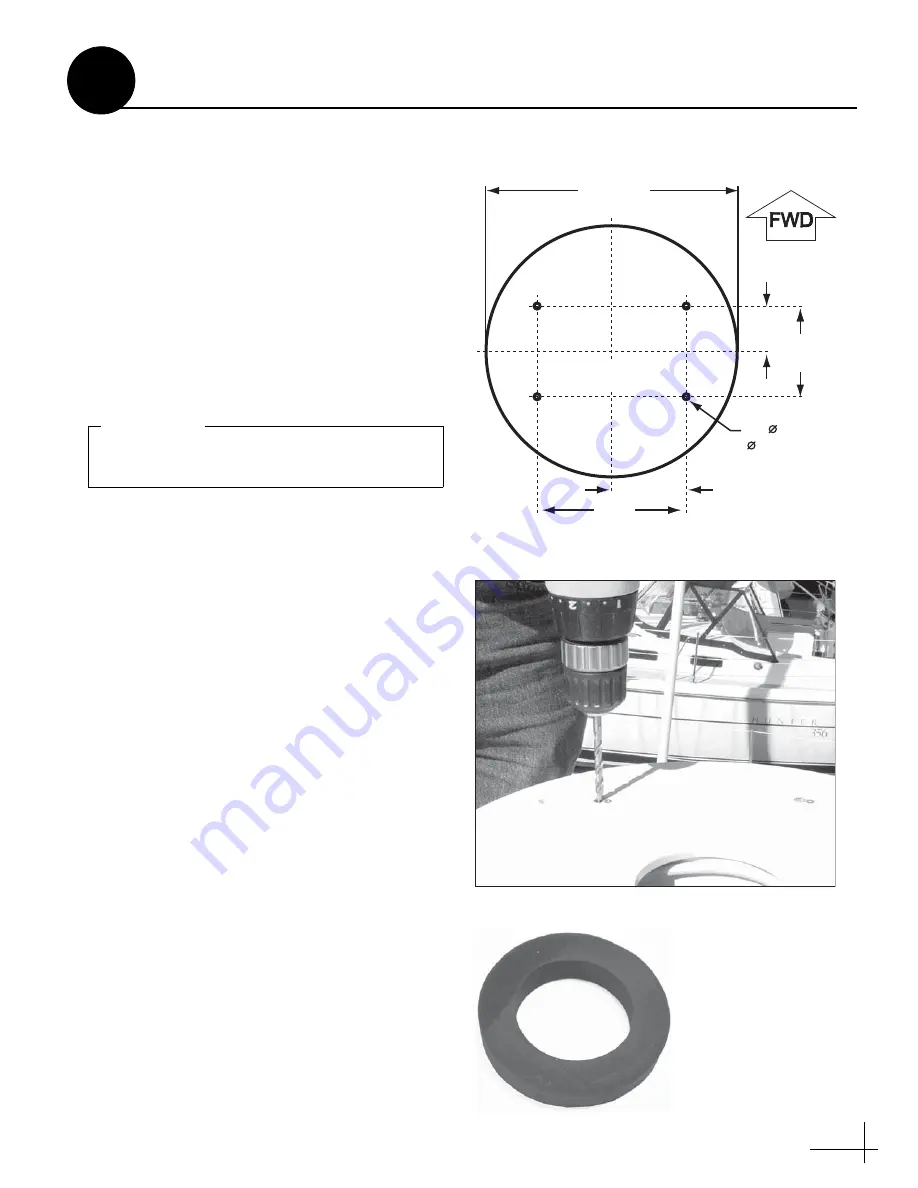

Peel off the paper backing from the supplied

foam seal to expose the adhesive. Then press

the foam seal down firmly onto the mounting

surface, centered between the antenna

mounting holes (see Figure 7).

X

15.5"

(39.4 cm)

2.8"

(7.1 cm)

5.6"

(14.2 cm)

4.6" (11.7 cm)

9.2"

(23.4 cm)

4 x 0.31"

( 0.8 cm)

Mounting Hole

s

C

a

ble Acce

ss

Hole

(Sugge

s

ted)

Antenn

a

B

as

e

Figure 5: Antenna Mounting Holes Layout

Be sure the mounting surface is flat and level.

Use a separate mounting plate, if necessary.

IMPORTANT!

Figure 6: Drilling Antenna Mounting Holes

Center

Between

Mo

u

nting

Holes

Figure 7: Foam Seal

Prepare the Mounting Site

3