8

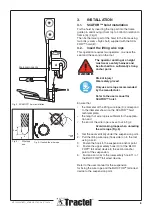

Check the safety of the suspension

structure at roof level and check

that no counterweight has been

removed (see PORTAFIX™ user

manual).

Each anchor point of the

suspension must be able to handle

a minimum load of 10 kN. If a

PORTAFIX™ or OMEGA is used,

refer to the load table for WLL=400

kg !

Make sure that the suspension

is placed directly in line with the

stirrup of the equipment (Fig. 10).

The operators must wear a hard hat

if the site conditions require it.

Wear safety gloves !

It is recommended that access to

the area at ground level below the

seat and which may be in line with

any object, tool or material falling

from the equipment be prevented

by being cordoned off. This recom-

mendation becomes a requirement

when the general public may have

access to this area.

The equipment is intended for use

in well lit areas either with natural or

artificial light. Under artificial light

the operator must have sufficient

light.

Ensure that along the facade of the

building there are no projections

with which may collide the

equipment.

When the work is completed, the

competent person must have the

seat taken out of service.

Danger

Danger

Danger

4.

OPERATING THE SEAT

4.1.

Specific safety rules

Only wire rope specified by the

TRACTEL Group should be used.

It should be replaced if any of the

defects indicated in chapter 6 are

observed.

It is forbidden to use the seat

without the fall arrest device

BLOCFOR

™

.

The BLOCFOR™ fall arrest device

is only efficient provided the upper

safety hook (10) is secured to the

suspension.

The fall arrest device will only fulfil

its function if the safety wire rope

between the suspension point and

its anchor point on the seat support

frame is taut.

Never work on the seat under

severe wind or storm conditions

(greater than 45 km/h)

The SUBITO seat is not designed to

allow the operator to sit on it other

than at ground level.

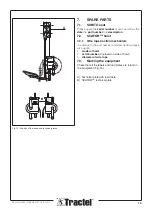

4.2. Preliminary checks

Check that the working load on the

equipment does not exceed the

value indicated on the load plate

secured to the stirrup.

Regularly check the correct

operation of the SCAFOR hoist,

the brake, and the fall arrest device

BLOCFOR

™

.

Particularly check the anchorage

and fixings of the suspension wire

rope and of the BLOCFOR

™

fall

arrest device at two different anchor

points. The collet of every safety

hook (10/11) must be tightly screwed

but not locked

Check the safety belt.

Danger

Danger

Danger

Warning

Warning

Warning

Warning

Warning

Warning

- MC1452-SUBITO_6FR-EN-D-IT-ES-NL 0

7

/201

8