Basic safety instructions

TR-Electronic GmbH 2013, All Rights Reserved

Printed in the Federal Republic of Germany

Page 14 of 29

TR - ECE - BA - GB - 0101 - 05

02/21/2018

2.9 First commissioning / Commissioning

Prior to the first commissioning the equipment is to be checked regarding its suitability

in the respective zone according to its labeling. The values indicated on the nameplate

are not to be exceeded. With use of the equipment in areas which are potentially

explosive because of dust, a deposit of dust on the top-side which is more than 5 mm

thick is not permissible. Here the installation of an additional covering may be required

in circumstances where the deposit of dust cannot be reliably avoided.

The operational safety of the equipment and the correct functional arrangement of the

equipment inside the plant must be checked before commissioning. It may only be

used in a clean and undamaged condition.

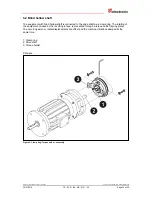

2.10 Assembly, installation and dismantling

With installation and operation of the explosion protective equipment, one should

consider protection against hazardous environmental influences which limit the

intended use of the equipment. This could be protection against aggressive fluids or

weather protection for example. During installation, the IEC 60079-14 and

DIN EN 60079-14 as well as other national standards and regulations applicable at the

installation site are to be adhered to.

The information on the nameplate must be complied with.

The assembly of the equipment takes place according to the enclosure's established

mounting possibilities, but impacts on the shaft such as from hammer blows are to be

avoided.

In potentially explosive areas, the equipment's power supply line with mating

connector is to be routed in such a way that it is protected from damage and

mechanical failure. The maximum connection information on the nameplate must be

complied with.

For metal enclosures in potentially explosive areas an equipotential line with at least

4 mm

2

is required.

Wiring work, opening and closing of electrical connections may only be performed with

the power switched off.

Do not perform any welding work once the equipment has already been wired and

switched on.

Touching the equipment-connection contacts with bare hands is to be avoided, or

the respective ESD-protective measures are to be implemented.