Assembly Instructions | ILM Servo Kits

24

Edition 03/2021 EN

Assembly

7.3.2 Rotor

►

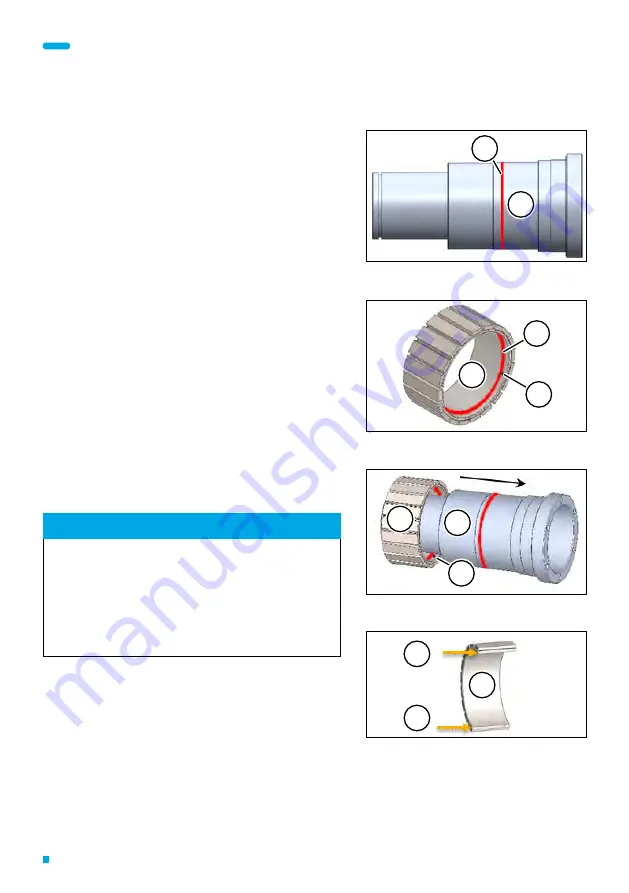

Clean and degrease the bonding surfaces on

the shaft (item 1 in Fig. 13) and rotor (item 1 in

Fig. 14) following the adhesive manufacturer’s

instructions.

►

Heat the shaft for 5 minutes at 60 °C in the

curing oven.

►

Following the manufacturer’s instructions,

apply a thin ring of adhesive (item 2 in Fig. 13)

to the bonding surface on the shaft (item 1 in

Fig. 13).

►

Following the manufacturer’s instructions, ap-

ply a thin ring of adhesive (item 2 in Fig. 14) to

the inner surface in the vicinity of the indexing

hole (item 3 in Fig. 14) on the rotor.

►

Align the rotor so that the indexing hole

(item 2 in Fig. 15) points towards the shaft (see

Fig. 15).

►

Push the rotor (item 1 in Fig. 15) onto the shaft

(item 3 in Fig. 15) and gently push it as far as it

will go.

NOTE

—

Do not press on the surfaces of the rotor

magnets as this will damage their coating.

—

Only press on the inner ring (item 1 in

Fig. 16) of the rotor when you push it onto

the shaft. The pressure points (item 2 in

Fig. 16) should be opposite one another.

►

Quickly remove any excess adhesive with a

dry cloth. Do not use solvents on the shaft or

magnets.

►

Carry out the curing process following the

adhesive manufacturer’s instructions.

Fig. 13: Adhesive ring on the shaft

1

2

Fig. 14: Adhesive ring on the rotor

1

2

3

Fig. 15: Pushing the rotor onto the shaft

1

2

3

Fig. 16: Pressure points on the inner ring

1

2

2