REMARKS

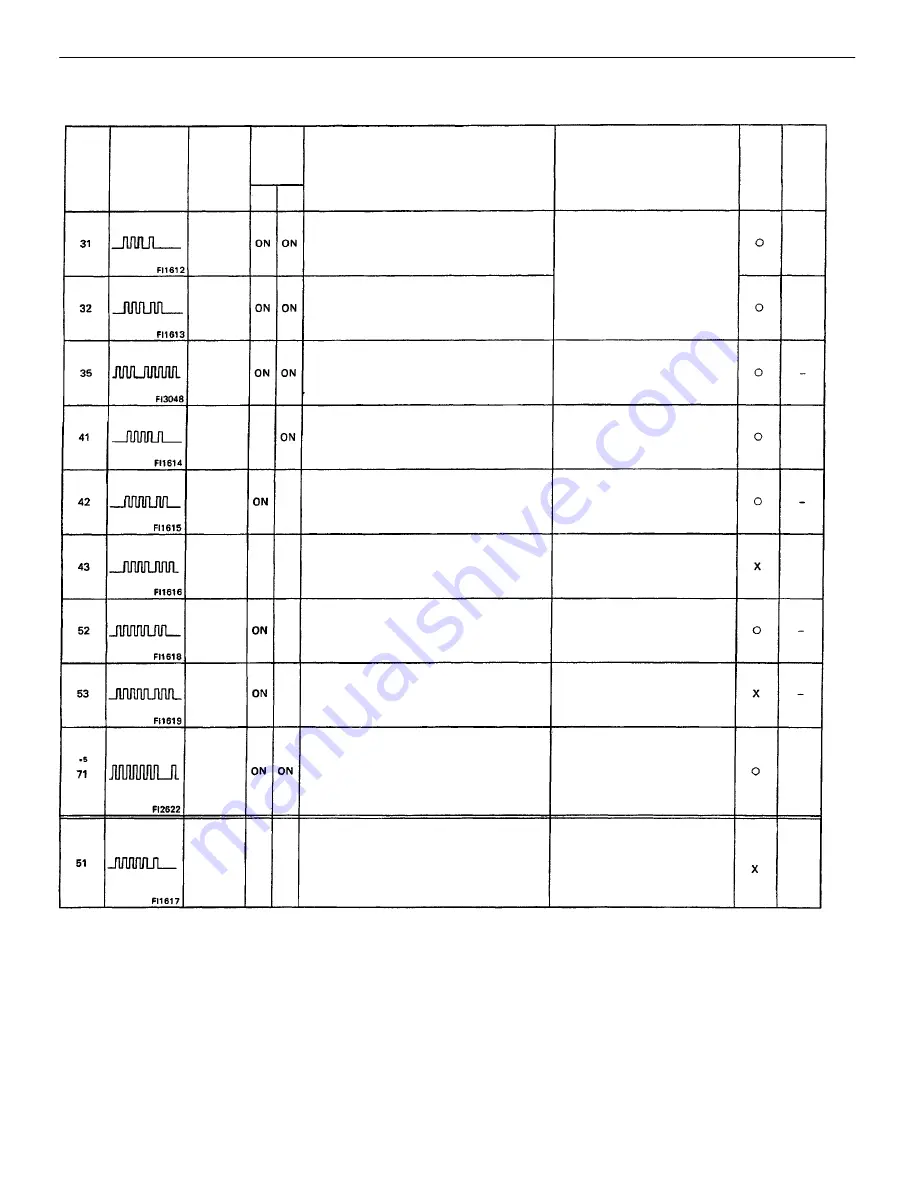

*1: ”ON’ displayed in the diagnosis mode column indicates that the malfunction indicator lamp is lighted up when a malfunction is detected. ”OFF”

indicates that

the ”CHECK” does not light up during malfunction diagnosis, even if a malfunction is detected. ”N.A.” indicates that the item is not included in

malfunction

diagnosis.

*2: ”O” in the memory column indicates that a diagnostic trouble code is recorded in the ECM memory when a malfunction occurs. ”X” indicates that a

diagnostic

trouble code is not recorded in the ECM memory even if a malfunction occurs. Accordingly, output of diagnostic results is performed with the IG SW

ON.

*3: The malfunction indicator lamp comes on if malfunction occurs only for California specifications,

*4: No. (2) in the diagnostic contents of codes No.25 and 26 apply to California and C&C specification vehicles only, while (1) applies to all models.

*5: Code 71 is used only for California specifications and C&C.

*6: “2 trip detection logic” (See page

*7: Except for California 2WD.

With the engine coolant temp. at 60

C (140

F)

or more, 240 seconds from start of EGR

operation.

The EGR gas temp. is less than 55

C ( 131

F)

and the EGR gas temp. has risen less than

20

C (36

C) during the 240 seconds.

*6 (2 trip detection logic)

•

Open in EGR gas temp. sen-

sor circuit

•

Open in VSV circuit for EG R

•

EGR vacuum hose discon-

nected, valve stuck

•

Clogged in EGR gas passage

•

ECM

At idling, open or short detected continuously

for 0.5 sec. or more in volume air flow meter

circuit.

•

Open – VC

•

Short – VC – E2

•

A/C switch circuit

•

Throttle position sensor 1 D L cir-

cuit

•

Park/Neutral position switch circuit

•

Accelerator pedal, cable

•

ECM

Open or short detected continuously for 0.5

sec: or more in volume air flow meter circuit.

•

Open – E2

•

short – VS – VC

DIAGNOSTIC TROUBLE CODES (Cont’d)

Open or short detected in throttle position

sensor

signal (VTA) for 0.5 sec. or more.

IDL contact is ON and VTA output exceeds

1.45 V.

SPD signal is not input to the ECM for at least

8 seconds during high load driving with engine

speed between 2,750 rpm and 4,000 rpm.

•

Open or short in starter signal

circuit

•

Open or short in IG SW or main

relay circuit

•

ECM

Displayed when A/C is ON, IDL contact OFF or

shift position in “R”, “D”, ”2”, or ”L” positions

with the DLC1 terminals E1 and TE1 connected.

Engine speed is between 650 rpm and 5,200

rpm

and engine control module (for knock control)

malfunction is detected.

With engine speed between 1,600 rpm – 5,200

rpm, signal from knock sensor is not

input to ECM for 6 revolution. (KNK)

Starter signal (STA) is not input to ECM even

once until engine reaches 800 rpm or more

when cranking.

•

open or short in volume air

flow

meter circuit

•

Volume air flow meter

•

ECM

•

Open or short in throttle posi-

tionsensor

circuit

•

Throttle position sensor

•

ECM

•

Open or short in vehicle speed

sensor circuit

•

Vehicle speed sensor

•

ECM

•

Open or short in knock sensor

circuit

•

Knock sensor (looseness, etc.)

•

ECM

Open or short detected in BARO sensor circuit

for 0.5 sec. or more.

Number of

blinks

Malfunction

Indicator

Lamp

*1

M aI–

function

Indicator

Lamp

6ARO

Sensor

Signal

(only

C&C)

Volume

Air Flow

Meter

Signal

Volume

Air Flow

Meter

Signal

Throttle

Position

Sensor

Signal

EGR

System

Mal–

function

Vehicle

Speed

Sensor

Signal

Switch

Condition

Signal

Knock

Control

signal

Knock

Sensor

Signal

Trouble Area

*2

Memory

Diagnosis

Starter

Signal

Code

No.

See

Page

System

•

ECM

•

ECM

*

3

ON

V02184

OFF

OFF

OFF

N.A.

N.A

.

N.A.

N.A.

Normal

Mode

Test

Mode

–

ENGINE

MFI SYSTEM

EG2–177

Summary of Contents for 22R-E

Page 1: ...INTRODUCTION INTRODUCTION IN 1 ...

Page 9: ...VEHICLE LIFT AND SUPPORT LOCATIONS INTRODUCTION VEHICLE LIFT AND SUPPORT LOCATIONS IN 9 ...

Page 35: ...22R E ENGINE ENGINE EG1 1 ...

Page 45: ...HINT Adjust idle mixture as necessary ENGINE ENGINE MECHANICAL EG1 11 ...

Page 49: ...CYLINDER HEAD COMPONENTS ENGINE ENGINE MECHANICAL EG1 15 ...

Page 80: ...CYLINDER BLOCK COMPONENTS ENGINE ENGINE MECHANICAL EG1 46 ...

Page 110: ...EXHAUST SYSTEM COMPONENTS ENGINE ENGINE MECHANICAL EG1 76 ...

Page 116: ...LAYOUT AND SCHEMATIC DRAWING Federal and Canada ENGINE EMISSION CONTROL SYSTEMS EG1 82 ...

Page 117: ...LAYOUT AND SCHEMATIC DRAWING Calif ENGINE EMISSION CONTROL SYSTEMS EG1 83 ...

Page 118: ...POSITIVE CRANKCASE VENTILATION PCV SYSTEM ENGINE EMISSION CONTROL SYSTEMS EG1 84 ...

Page 126: ...EXHAUST GAS RECIRCULATION EGR SYSTEM Calif ENGINE EMISSION CONTROL SYSTEMS EG1 92 ...

Page 135: ...MFI SYSTEM DESCRIPTION ENGINE MFI SYSTEM EG1 101 ...

Page 211: ...FUEL PUMP ENGINE MFI SYSTEM EG1 177 ...

Page 226: ...FUEL TANK AND LINE COMPONENTS ENGINE MFI SYSTEM EG1 192 ...

Page 230: ...3 INSTALL INTAKE AIR CONNECTOR ENGINE MFI SYSTEM EG1 196 ...

Page 239: ...2 INSTALL THROTTLE BODY See page EG1 202 ELECTRONIC PARTS LOCATION ENGINE MFI SYSTEM EG1 205 ...

Page 278: ...3VZ E ENGINE ENGINE EG2 1 ...

Page 299: ... ENGINE ENGINE MECHANICAL EG2 22 ...

Page 300: ... ENGINE ENGINE MECHANICAL EG2 23 ...

Page 326: ...CYLINDER HEAD COMPONENTS ENGINE ENGINE MECHANICAL EG2 49 ...

Page 327: ... ENGINE ENGINE MECHANICAL EG2 50 ...

Page 367: ...CYLINDER BLOCK COMPONENTS ENGINE ENGINE MECHANICAL EG2 90 ...

Page 411: ...EXHAUST SYSTEM ENGINE ENGINE MECHANICAL EG2 134 ...

Page 419: ...LAYOUT AND SCHEMATIC DRAWING ENGINE EMISSION CONTROL SYSTEMS EG2 142 ...

Page 435: ...MFI SYSTEM SYSTEM CIRCUIT DESCRIPTION ENGINE MFI SYSTEM EG2 158 ...

Page 476: ... ENGINE MFI SYSTEM EG2 199 ...

Page 497: ...INJECTOR COMPONENTS FOR REMOVAL AND INSTALLATION ENGINE MFI SYSTEM EG2 220 ...

Page 508: ...FUEL TANK AND LINE COMPONENTS ENGINE MFI SYSTEM EG2 231 ...

Page 521: ...ELECTRONIC PARTS LOCATION ENGINE MFI SYSTEM EG2 244 ...

Page 569: ...IGNITION SYSTEM IGNITION SYSTEM IG 1 ...

Page 596: ...STARTING SYSTEM STARTING SYSTEM ST 1 ...

Page 597: ...STARTER COMPONENTS STARTING SYSTEM Starter ST 2 ...

Page 609: ...CHARGING SYSTEM CHARGING SYSTEM CH 1 ...

Page 613: ...GENERATOR COMPONENTS CHARGING SYSTEM Generator CH 5 ...