- 3 -

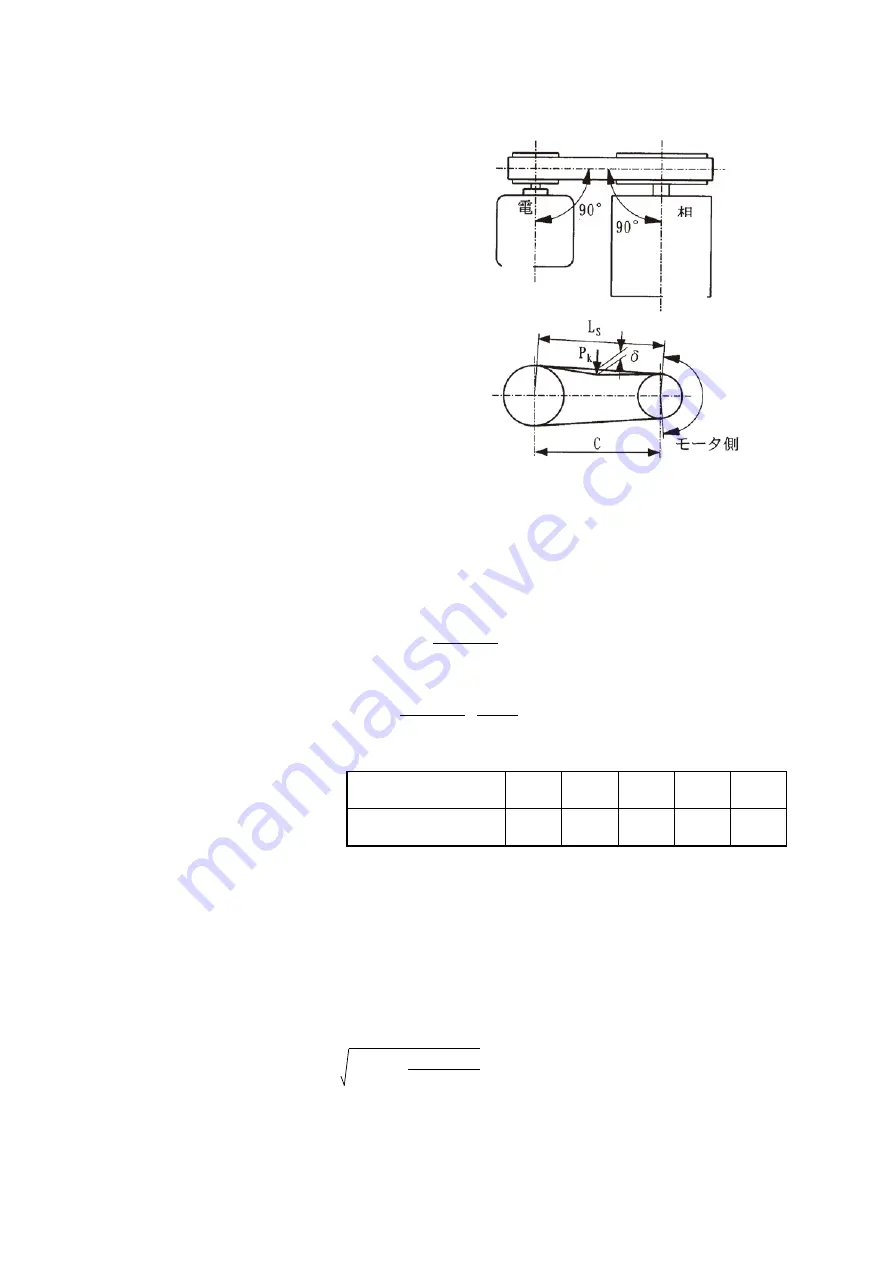

(3) In case of belt drive

Set the counterpart machine shaft and motor

shaft accurately parallel and apply the belt in

such a way that both pulley centers coincide each

other.

The belt is apt to be stretched too much however,

excessive stretching will damage the bearing and

cause unexpected accidents such as breakage of

motor shaft, etc., to which please pay attention.

1) Belt stretching method

Step 1 : Firstly, find the belt span (Ls). Belt span

is the length of the portion of belt

between contact points with both pulleys.

Step 2 : Apply the force ( Pk ), which is required

for deflection ( δ ), at the center of the

belt span. This required force for

deflection ( δ ) should be calculated by

the formula 5 shown below and it should

be within the range of Pk1 - Pk2.

Step 3 : Stretch the belt in such a way that the

deflection ( δ ), when the force is applied,

will be the value found by the following

formula.

δ

= 0.016

・

Ls

2) Calculation formula

Step 1 : How to find belt contact angle (small pulley side) ... Formula 1

Formula 1

θ = 180°

-

2 sin

-1

Step 2 : How to find initial tension (Fo) .................................. Formula 2

Formula 2

Fo = 0.9 { 500 ( ) + m

・

v

2

}

Fo : Initial tension (N)

Table 1

K

θ

: Contact angle

correction factor

Contact angle (

θ

)

140

°

150

°

160

°

170

°

180

°

P

d

: Design power (kW)

Correction factor (K

θ

)

0.89

0.92

0.95

0.98

1

P

d

= P

N

x ( Ko + Ki )

P

N

: Load power (motor output, in general) (1kW)

Ko : Load correction factor (1.0

~

1.5)

Ki : Idler correction factor (0

~

0.2)

Z : Number of belt v : Belt speed (m/sec) m : Mass/unit of belt (kg/m)

Note) Determine Ko, Ki depending on the machine to be used and operation time,

referring JIS Standard or catalog, etc. of belt maker.

Step 3 : How to find span (Ls) ................................. Formula 3

Formula 3

Ls : Span (mm)

C : Distance between shafts (mm)

d

2

: Large pulley nominal diameter

(mm)

d

1

: Small pulley nominal diameter

(mm)

Z

・

v

P

d

d

2

-

d

1

2C

Mo

to

r

C

ount

er

pa

rt

m

ac

hi

ne

Motor side

pulley

θ(Belt cont-

act angle)

Fig. 3 Belt stretching method

2.5 – K

θ

K

θ

Ls = C

2

-

(d

2

-

d

1

)

2

4