BD4603

17

TLGS625

TR

OUBLESHOO

TING GUIDE

Problem(s)

Possible Cause(s)

Suggested Solution(s)

Wheel dulls quickly,

grit falls off.

1. Depth of cut too great.

2. Wheel is soft.

3. Wheel diameter too small.

4. Bad wheel dress.

5. Defective wheel bonding.

1. Slow down the rate of movement

of the workpiece into w heel.

2. Wheel too soft for the material.

being ground, select harde r bond.

3. Replace the wheel.

4. Dress the wheel.

5. Consult manufacturer of grinding

wheel.

Wheel clogs and

workpiece shows

burn marks.

1. Wheel is too hard.

2. Feed rate too slow.

3. Bad wheel dress.

4. Coolant required.

1. Wheel too hard for the material

being ground, select softer bond .

2. Increase the rate of movement of

the workpiece into wheel.

3. Dress the wheel.

4. A dd optional coolant system or

introduce coolant by hand.

Summary of Contents for TLGS625

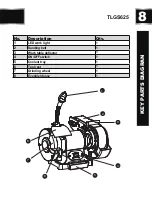

Page 18: ...18 EXPLONED VIEW TLGS625...