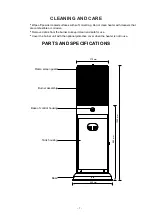

C E I L I N G

W

A

L

L

100 cm

100 cm

Ÿ

Use a 9 kg LPG cylinder only.

Ÿ

The hose must comply with the requirements of SANS 1156-2 or BS 2312.

Ÿ

A dented, rusted or damaged LPG cylinder may be hazardous and should not be used.

Ÿ

Never use a cylinder with a damaged valve connection.

Ÿ

The cylinder valve must have a horizomtal outlet with a G5/8 left hand thread to suit the regulator.

Ÿ

Never connect the cylinder directly to the heater. A regulator must always be used.

Ÿ

The regulator must comply with the requirements of SANS 1237 and must have a G3/8 right hand threaded

connector.

Ÿ

Make sure the rubber seal on the regulator connector is in place and in good condition before connecting

the regulator to the cylinder valve.

Ÿ

The heater is for outdoor use only. Always ensure that adequate fresh

air ventilation is provided.

Ÿ

Always maintain proper clearance to combustible materials, i.e. top

100 cm and sides 100 cm minimum.

Ÿ

The heater must be placed on firm level ground

Ÿ

Never operate heater in areas where petrol or other flammable liquids

or vapours are stored.

HEATER STAND AND LOCATION

GAS REQUIREMENTS

LEAKAGE TEST

Ÿ

Gas connections on the heater are leak tested at the factory prior to shipment. A complete gas tightness

check must be performed at the installation site due to possible mishandling in shipment or excessive

pressure being applied to the heater.

Ÿ

Make a soap solution of one part liquid detergent and one part water. The soap solution can be applied with

a spray bottle, brush or rag. Soap bubbles will appear in case of a leak.

Ÿ

The heater must be checked with a full cylinder.

Ÿ

Make sure the safety control valve on the appliance is in the OFF position.

Ÿ

Connect the regulator with the gas hose secured to the regulator outlet and to the gas inlet on the appliance

to the cylinder valve.

Ÿ

Turn the gas supply ON by opening the cylinder valve.

Ÿ

Check for leaks by brushing or spraying the soapy solution over the connection joints

Ÿ

In case of a leak, turn off the gas supply by closing the cylinder valve. Tighten any leaking connections, then

turn the gas supply on and re-check.

Ÿ

Never leak test while smoking.

Ÿ

If unable to prevent a leak, call a service technician to examine the appliance and do not use it until the

technician has declared it safe to do so

- 5 -