– 38 –

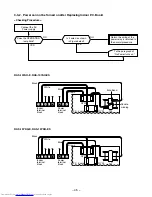

8-5-3. Vacuum Pumping

INFORMATION

In order to prevent any other refrigerant from being

charged accidentally, each port of the manifold has

been changed in shape.

Differences in Port Size between Conventional

R22 and R410A

Port

size

Manifold for R22

Manifold for R410A

7/16 UNF

1/2 UNF

20 threads per inch

20 threads per inch

AIR PURGE

Evacuate the air in the connecting pipes and in

the indoor unit using vacuum pump.

Do not use the refrigerant in the outdoor unit.

For details, see the manual of vacuum pump.

<Use of vacuum pump>

(1) Connect the charge hose (A) from the manifold

valve to the charge inlet of the gas side packed

valve.

(2) Connect the charge hose (B) to the port of

vacuum pump.

(3) Open fully the low pressure side handle of the

manifold valve.

(4) Operate the vacuum pump.

(5) Close the low pressure side handle of manifold

valve after vacuumizing and stop the vacuum

pump.

Continue vacuumizing more than 15 minutes and

check the pressure gage indicates –0,1MPa

(–76 cmHg).

(6) Open the stems of packed valves A and B all the

way.

(7) Securely tighten the stem cap to each of the

packed valve stems.

VP

Outdoor unit

Charge

hose (B)

Service port

Packed

valve

A

B

C

D

Gas

(Ø9,52)

Liquid

(Ø6,35)

Indoor unit

Lo

Hi

High pressure

side handle

Pressure gage

Manifold valve

Low pressure side handle

Charge hose (A)

Fig. 8-5-5

CAUTION

• KEEP IMPORTANT 4 POINTS FOR

INSTALLATION (PIPING WORK)

(1) Take away dust and moisture (Inside of the

connecting pipes.)

(2) Tight connection (between pipes and unit)

(3) Evacuate the air in the connecting pipes using

VACUUM PUMP.

(4) Check gas leak (connected points)

<Packed Valve Handling Precautions>

• Open the valve stem all the way out; so not try

to open it beyond the stopper.

• Securely tighten the valve stem cap with the

wrench or like.

• Valve stem cap tightening torque is as follows;

Gas pipes side (Ø12,7) : 49 ~ 62 N•m (5,0 ~ 6,2 kgf•m)

Gas pipes side (Ø9,52) : 30 ~ 42 N•m (3,0 ~ 4,2 kgf•m)

Liquid pipe side (Ø6,35) : 16 ~ 18 N•m (1,6 ~ 1,8 kgf•m)

Service port cap

: 9 ~ 10 N•m (0,9 ~ 1,0 kgf•m)

<A5 mm hexagon wrench is required.>

5mm

Flare nut

Stopper

Wrench

Valve body

Valve stem

Service port cap

Service port

Valve stem cap

Note :

Service port at Gas pipes valve only.

Fig. 8-5-6