Alignment and Adjustment

Toshiba

5-5

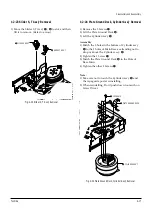

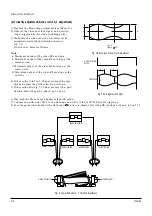

a. ACE HEAD HEIGHT ADJUSTMENT

1) Run the alignment tape (Color bar) in the playback

mode.

2) Observe surface of the audio head using a dental

mirror.

3) Turn screw (C) clockwise or counterclockwise until

the gap of lower tape edge and the lower edge of

the control head is about 0.25mm.

(Refer to Fig. 5-6 and 5-7)

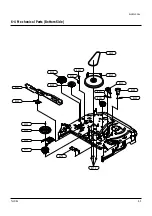

Fig. 5-6 Location of ACE Head Adjustment Screw

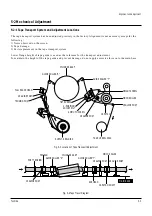

Fig. 5-7 ACE Head Height Adjustment

SCREW (A)

TLIT ADJUST

X-POSITION

ADJUSTING SLIT

SCREW (C)

HEIGHT ADJUST

SCREW (D)

X-POSITION LOCKING

SCREW (B)

AZIMUTH ADJUST

0 ~ 0 .25 mm

AUDIO HEAD

VIDEO HEAD

CONTROL HEAD

b. ACE HEAD TILT ADJUSTMENT

1) Playback a blank tape and observe the position of

the tape at the lower flange of tape guide.

2) Confirm that there is no curl or wrinkle at the

lower flange of tape guide as shown in Fig. 5-8 (B).

3) If a curl or wrinkle of the tape occurrs, slightly

turn the screw (A) tilt adjust on the ACE head ass’y.

4) Reconfirm the ACE head height.

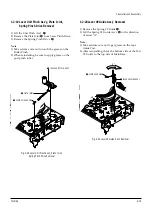

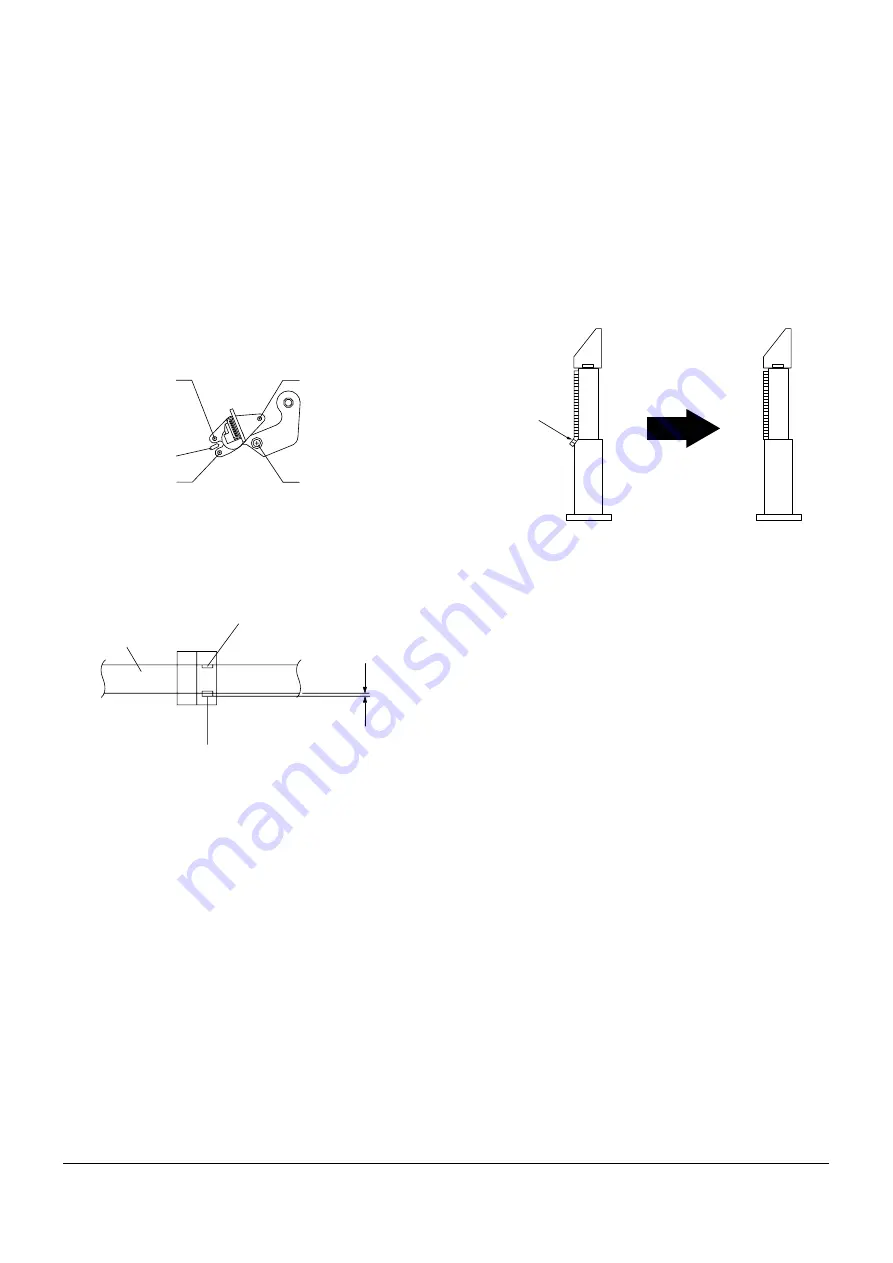

Fig. 5-8 Tape Guide Check

c. AUDIO AZIMUTH ADJUSTMENT

1) Load alignment tape (Mono scope) and playback

the 7KHz signal.

2) Connect channel-1 scope probe to audio output

test point (TP302).

3) Adjust screw (B) to achieve maximum audio level.

(See Fig. 5-6)

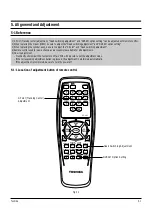

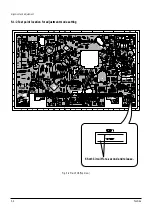

d. ACE HEAD POSITION (X-POINT) ADJUSTMENT

1) Playback the alignment tape (Color bar).

2) Monmently short-circuit the test point on Main

PCB with pincers to set the adjustment mode.

(See Fig. 5-2 )

3) Press the “5” button of remote control then adjust-

ment is operated automatically. (See Fig. 5-1)

4) Connect the CH-1 probe to TP301 (Envelope) the

CH-2 probe to TP602 (H’D switching pulse) and

then trigger to CH-1.

5) Insert the (-) driver into the X-Point adjustment

hole and adjust it so that envelope wavwform is

maximum.

6) Turn the Power off.

(A)

(B)

(BAD)

WRINKLE

(GOOD)