Disassembly and Reassembly

Toshiba

4-11

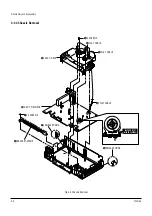

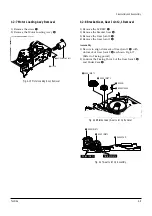

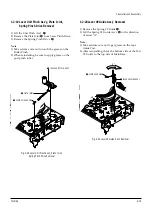

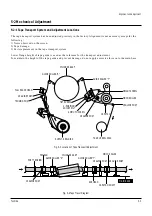

1-2-12 Lever Tension Ass’y,

Band Brake Ass’y Removal

1) Remove the Lever Brake S Ass'y (Refer to Fig 4-22)

2) Remove the Spring Tension Lever

Œ

.

3) Rotate stopper of Main Base in the direction of

arrow “A”.

4) Lift the Lever Tension Ass'y

´

& Band brake

Ass'y

ˇ

.

Note

:

1) When replacing the Lever Tension Ass'y

´

, be sure

to apply Grease on the post,

2) Take care not to touch stain on the felt side, and not

to be folder and broken Band brake Ass'y

3) After Lever Tension Ass'y seated, Rotate stopper of

Main Base to the Mark[B].

Œ

SPRING TENTION LEVER

STOPPER

MARK[B]

"A"

´

LEVER TENTION ASS`Y

ˇ

BAND BRAKE ASS`Y

Fig. 4-21 Lever Tension Ass’y,

Band Brake Ass’y Removal

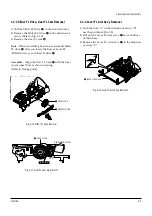

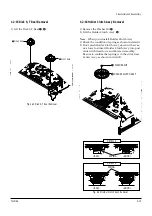

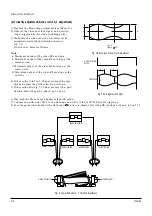

1-2-11 Lever Pinch Drive,

Lever Tension Drive Removal

1) Remove the Lever Pinch Drive

Œ

, Lever Tension

Drive

´

.

Œ

LEVER PINCH DRIVE

´

LEVER TENSION DRIVE

Fig. 4-20 Lever Pinch Drive,

Lever Tension Drive Removal