(ii)

Safety Summary

EO1-33019

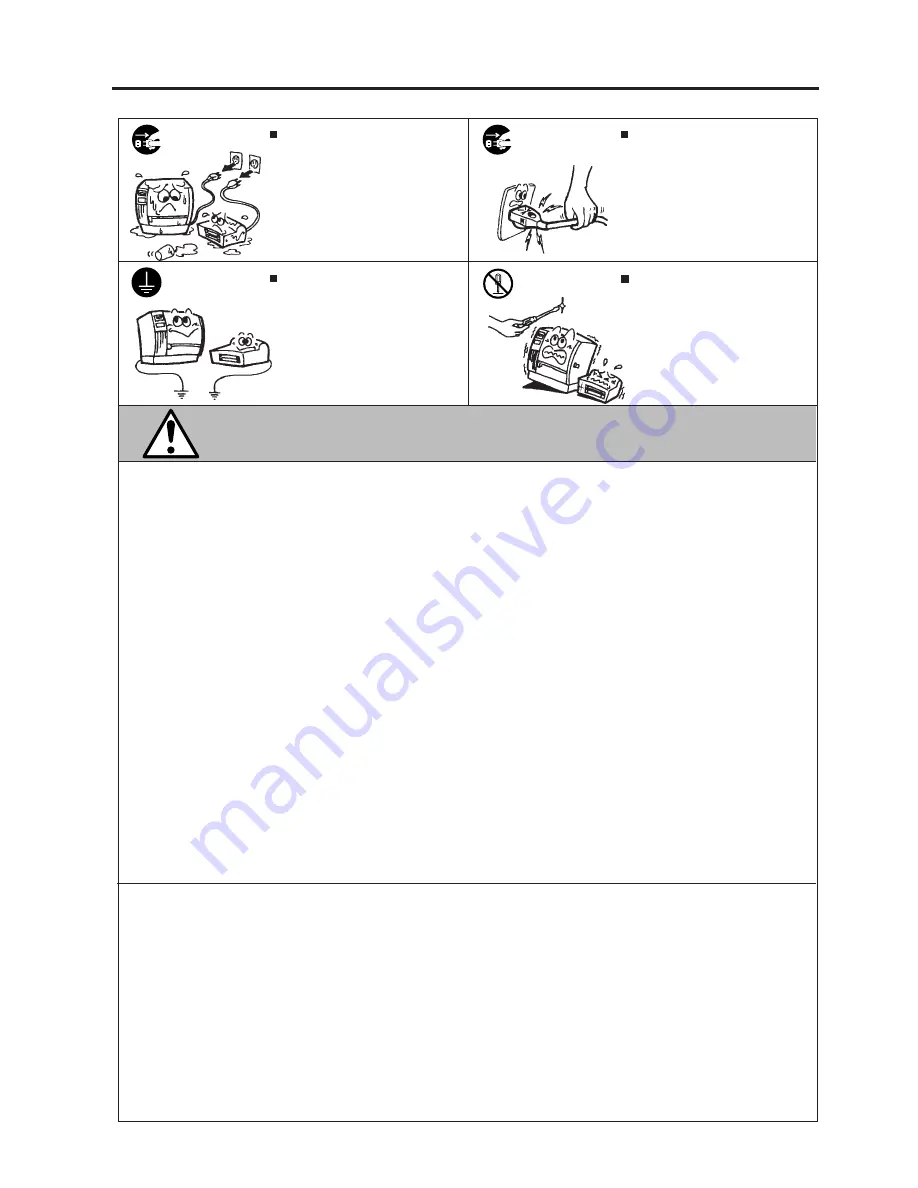

CAUTION

This indicates that there is the risk of personal Injury or damage to

objects if the machines are improperly handled contrary to this indication.

If foreign objects (metal fragments,

water, liquids) enter the machines,

first turn off the power switches and

disconnect the power cord plugs from

the outlet, and then contact your

authorized TOSHIBA TEC repre-

sentative for assistance. Continued

use of the machine in that condition

may cause fire or electric shock.

Disconnect

the plug.

Do not remove covers, repair or

modify the machine by yourself. You

may be injured by high voltage, very

hot parts or sharp edges inside the

machine.

No disassem-

bling.

Ensure that the equipment is

properly grounded. Extension cables

should also be grounded. Fire or

electric shock could occur on

improperly grounded equipment.

Connect a

grounding

wire.

When unplugging the power cords,

be sure to hold and pull on the plug

portion. Pulling on the cord portion

may cut or expose the internal wires

and cause fire or electric shock.

Disconnect

the plug.

Precautions

The following precautions will help to ensure that this machine will continue to function correctly.

•

Try to avoid locations that have the following adverse conditions:

*

Temperatures out of the specification

*

Direct sunlight

*

High humidity

*

Shared power source

*

Excessive vibration

*

Dust/Gas

•

The cover should be cleaned by wiping with a dry cloth or a cloth slightly dampened with a mild

detergent solution. NEVER USE THINNER OR ANY OTHER VOLATILE SOLVENT on the plastic

covers.

•

USE ONLY TOSHIBA TEC SPECIFIED paper and ribbons.

•

DO NOT STORE the paper or ribbons where they might be exposed to direct sunlight, high tem-

peratures, high humidity, dust, or gas.

•

Ensure the printer is operated on a level surface.

•

Any data stored in the memory of the printer could be lost during a printer fault.

•

Try to avoid using this equipment on the same power supply as high voltage equipment or equip-

ment likely to cause mains interference.

•

Unplug the machine whenever you are working inside it or cleaning it.

•

Keep your work environment static free.

•

Do not place heavy objects on top of the machines, as these items may become unbalanced and fall

causing injury.

•

Do not block the ventilation slits of the machines, as this will cause heat to build up inside the

machines and may cause fire.

•

Do not lean against the machine. It may fall on you and could cause injury.

•

Care must be taken not to injure yourself with the printer paper cutter.

•

Unplug the machine when it is not used for a long period of time.

Request Regarding Maintenance

•

Utilize our maintenance services.

After purchasing the machine, contact your authorized TOSHIBA TEC representative for assistance

once a year to have the inside of the machine cleaned. Otherwise, dust will build up inside the

machines and may cause a fire or a malfunction. Cleaning is particularly effective before humid

rainy seasons.

•

Our preventive maintenance service performs the periodic checks and other work required to

maintain the quality and performance of the machines, preventing accidents beforehand.

For details, please consult your authorized TOSHIBA TEC representative for assistance.

•

Using insecticides and other chemicals

Do not expose the machines to insecticides or other volatile solvents. This will cause the cabinet or

other parts to deteriorate or cause the paint to peel.