– 82 –

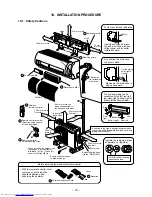

1. Piping connections to the outdoor unit should be

arranged in the sequence A, B, C, D starting from

the bottom.

(For each piping connection, the gas pipe is on the

bottom and the liquid pipe is on the top.)

2. When multiple indoor units are to be connected to

the outdoor unit, make the ends of the pipes and

wires from each indoor unit to ensure that they will

be connected to the outdoor unit correctly.

(Problems caused by indoor units being connected

to the outdoor unit incorrectly are very common in

multiple-unit installations.)

3. The length and height difference of the connecting

pipes between the indoor and outdoor units must

be within the ranges indicated below.

• Total piping length :

4 units (A + B + C + D) Multi,

Non. Additional refrigerant 70 m

3 units (A + B + C) Multi,

Non. Additional refrigerant 50 m

• Minimum piping length :

A or B or C or D = 2 m or more

• Maximum indoor piping length :

A or B or C or D = 25 m or less

• Maximum piping height difference :

A or B or C or D = 15 m or less

• Maximum piping/height

difference between 2 units

= 15 m or less

Tightening connection

Align the centers of the connecting pipes and tighten

the flare nut as far as possible with your fingers. Then

tighten the nut with a spanner and torque wrench as

shown in the figure.

CAUTION

• Do not apply excess torque.

Otherwise, the nut may break.

(Unit : N·m)

Fig. 10-4-7

4. Connect 2 or more indoor units for heat pump.

5. If the outdoor units is to be mounted on a wall,

make sure that the platform supporting it is suffi-

ciently strong. The platform should be designed

and manufactured to maintain its strength over a

long period of time, and sufficient consideration

should be given to ensuring that the outdoor unit

will not fall.

6. When the outdoor unit is to be mounted high on a

wall, take particular care to ensure that parts do

not fall installer is protected.

7. When doing installation work on level ground, it is

usual to wiring and piping connections to the

indoor units. And/then make to the outdoor unit.

However if outdoor work is difficult it is possible

instead to make changes to the procedure.

For example by making adjustments to the wiring

and piping length on the inside (rather than the

outside).

How to remove the side panel

1. Remove 3 screws

of the side panel.

2. Pull the side

panel downward.

Fig. 10-4-8

Side panel

Outdoor

unit

15 m or less

A

B

C

D

• Tightening torque of flare pipe

The pressure of R410A is higher than R22. (Approx.

1.6 times) Therefore securely tighten the flare pipes

which connect the outdoor unit and indoor unit with

the specified tightening torque using a torque

wrench.

If any flare pipe is incorrectly

connected, it may cause not

only a gas leakage but also

trouble in the refrigeration cycle.

3M26

4M27

Connectable capacity class

A

B

C

D

Total

10, 13

16

16

—

(with reducer) (with expander) (with expander)

45

16

10, 13

10, 13

—

10, 13

16

16

16

(with reducer) (with expander) (with expander) (with expander)

52

16

10, 13

10, 13

10, 13

Outer dia. of copper pipe

Ø6.35 mm

Ø9.52 mm

Ø12.7 mm

Tightening torque

14 to 18 (1.4 to 1.8 kgf•m)

33 to 42 (3.3 to 4.2 kgf•m)

50 to 62 (5.0 to 6.2 kgf•m)

Fig. 10-4-9

Fig. 10-4-10

Fig. 10-4-11

Half union

Flare nut

Externally

threaded side

Internally

threaded side

Use a wrench to secure.

Use a torque wrench to tighten.

Outdoor

unit

Indoor unit

D

D UNIT

4M27 only

Ø6.35

Ø9.52

A

A UNIT

Ø6.35

Ø12.7

C

C UNIT

Ø6.35

Ø9.52

B

B UNIT

Ø6.35

Ø9.52

Flare at

indoor

unit side

Flare at

outdoor

unit side

Summary of Contents for RAS-3M26GAV-E

Page 121: ... 121 MCC 1438 ...

Page 122: ... 122 MCC 818 ...