9

Toshiba 1115551210 (EN)

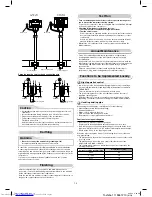

2. Insert a fl are nut into the pipe and fl are the pipe.

Projection margin in fl aring : A (Unit : mm)

Rigid (clutch type)

Outer dia.

of copper pipe

A

R410A tool used

Conventional

tool used

∅

9.52 mm

0 to 0.5

1.5 to 2.0

∅

15.88 mm

1.0 to 1.5

2.0 to 2.5

Flaring dia. meter size : A (Unit : mm)

Outer dia. of copper pipe

+0

–0.4

A

∅

9.52 mm

13.2

∅

15.88 mm

19.7

* In case of fl aring for R410A with the conventional fl are tool, pull it out

approx. 0.5 mm more than that for R22 to adjust to the specifi ed fl are size.

The copper pipe gauge is useful for adjusting the projection margin size.

Piping connection

Liquid side

Outer diameter

Thickness

∅

9.52 mm

0.8 mm

Gas side

Outer diameter

Thickness

∅

15.88 mm

1.0 mm

A

90

Refrigerant Piping Connection

Refrigerant Piping

Tightening of connecting part

1. Align the centers of the connecting pipes and fully tighten the fl are nut

with your fi ngers. Then fi x the nut with a wrench as shown in the fi gure

and tighten it with a torque wrench.

Flaring

1. Cut the pipe with a pipe cutter.

Knockout of pipe cover

Knockout procedure

Obliquity

Roughness

Warp

Pipe

Die

Half union or packed valve

Fix with wrench.

Flare nut

Tighten with torque wrench.

Internally

threaded side

Externally

threaded side

• The indoor/outdoor connecting pipes can be connected in 4 directions.

Take off the knockout part of the pipe cover through which pipes or wires

will pass through the base plate.

• Detach the pipe cover and tap on the knockout section a few times with

the shank of a screwdriver. A knockout hole can easily be punched.

• After punching out the knockout hole, remove burrs from the hole and

then install the supplied protective bush and guard material around the

passage hole to protect wires and pipes.

Be sure to attach the pipe covers after pipes have been connected. Cut

the slits under the pipe covers to facilitate the installation.

After connecting the pipes, be sure to mount the pipe cover. The pipe

cover is easily mounted by cutting off the slit at the lower part of the pipe

cover.

* Be sure to wear heavy work gloves while working.

Rear direction

Pipe cover

Side direction

Front direction

Down direction

Supplied protective bush

Supplied passage hole guard material

* Attach the guard material securely

so that it does not come loose.

A

2. As shown in the fi gure, be sure to use two wrenches to loosen or tighten

the fl are nut of the valve on the gas side. If you use a single crescent, the

fl are nut cannot be tightened to the required tightening torque.

On the other hand, use a single crescent to loosen or tighten the fl are nut

of the valve on the liquid side.

TSB 1115551210_EN.indb 9

TSB 1115551210_EN.indb 9

6/18/14 9:03 AM

6/18/14 9:03 AM