FILE NO. SVM-04022

– 40 –

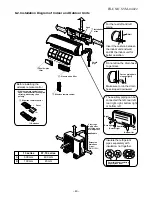

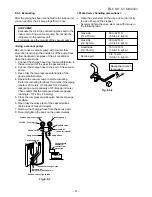

8-2. Installation Diagram of Indoor and Outdoor Units

13 series

07, 10 series

A

600 mm

400 mm

B

100 mm

45 mm

600 mm or more

B mm

or more

100 m

m or m

ore

A m

m o

r m

ore

600 m

m o

r m

ore

Vinyl tape

Apply after

carrying out a

drainage test.

Extension

drain hose

(Option:

RB–821SW)

Insulate the refrigerant

pipes separately with

insulation, not together.

For the rear left and left

piping

Insert the cushion between

the indoor unit and wall,

and tilt the indoor unit for

better operation.

Wall

6 mm thick heat resisting

polyethylene foam

Saddle

Do not allow the drain hose

to get slack.

Make sure to run the drain

hose sloped downward.

Cut the piping hole

sloped slightly

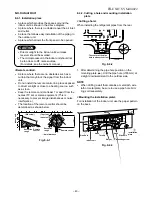

Before installing the

wireless remote control

• With the remote control cover

open, load the batteries supplied

correctly, observing their

polarity.

Shield

pipe

Air filt

er

Hook

Hook

(Atta

ch to

the fr

ont p

anel.)

65 mm or more

170 m

m or m

ore

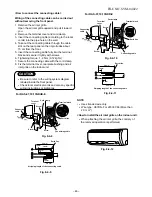

1

Installation

plate

2

Wireless remote control

170 mm or more

4

Zeolite-plus

filter

6

Plasma air purifier

3

Batteries

2

Wireless remote control

Cover

The auxiliary piping can be

connected the left, rear left,

rear right, right, bottom right

or bottom left.

Right

Rear right

Bottom right

Left

Rear left

Bottom left