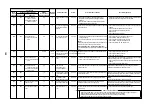

133

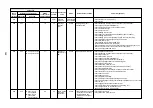

Check code

Outdoor 7-segment display

Main

remote

controller Check code

Sub-code

AI-NET

central control

remote controller

Detected

position

Check code

name

Status

Error detection condition

Check item (position)

P07

P07

01: Compressor

1 side

02: Compressor

2 side

1C

IPDU

I/F

Heat sink

overheat error

All stop

IGBT built-in temp sensor (TH)

was overheated.

• Check power voltage.

• Check outdoor fan system error.

• Check clogging of heat sink cooling duct.

• Check fixation between IGBT and heat sink. (Check screwing and contact.)

• Check IPDU error.(IGBT built-in temp sensor (TH) error).

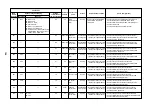

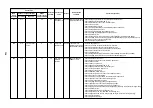

P10

P10

Indoor address

with trouble

Ob

Indoor

Indoor

overflow error

All stop

• Float switch operated.

• Float switch circuit

disconnected or the

connector came off.

• Check the float switch connector.

• Check operation of drain pump unit.

• Check the drain pump circuit.

• Check clogging of drain pipe.

• Check indoor P.C. board error.

P12

—

—

11

Indoor

Indoor fan

motor error

Corresponding

unit only stops.

The standard ducted unit air conditioner utilizes a direct current (DC) indoor fan motor that features current

limiting protection. In the event power is not isolated prior to service, the protective control circuit will activate

and stop the unit operating. The check code “P12”will be displayed on the remote controller-once service work

has been completed, this code can be cleared by switching off then on the electrical isolation device of the

indoor unit and pressing the operation stop button on the remote controller to reset the system

• The value of motor speed

deviated from target value

was detected for certain time.

• Over-current protection

operated.

• Check connection of fan connector and wiring.

• Check fan motor error.

• Check indoor P.C. board error.

• Check influence of outside air control.

• Check indoor type code (DN=10) and the capacity code (DN=11).

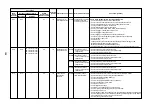

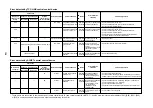

P13

P13

—

47

I/F

Outdoor liquid

back

detection

error

All stop

In heating

While the system is operating

in HEAT mode, outdoor PMV of

which opening degree was 100

pulse or less for a certain time.

• Check full close operation of outdoor PMV (1, 2).

• Check Pd and Ps sensor error.

• Check clogging of SV2 circuit.

• Check clogging of 4-way valve error circuit.

• Check outdoor P.C. board (I/F) error.

• Check capillary clogging of oil return circuit from oil separator.

• Check TS1, TS2 sensor error.

01: TS condition

AE

I/F

Gas leak

detection

(TS1

condition)

All stop

Suction temp exceeded the

judgment standard temp for 10

minutes or more.

TS error judgment standard

temperature

In cooling operation: 60°C or

higher

In heating operation: 40°C or

higher

• Check refrigerant shortage.

• Check full open of outdoor service valves (gas side, liquid side).

• Check outdoor PMV clogging (PMV1, 2).

• Check characteristics of TS1 sensor resistance value.

• Check 4-way valve error.

• Check leakage of SV4 circuit.

• Check leakage of SV5 circuit.

• Check mispiping of discharge gas/suction gas main pipe.

• Check Flow selector unit.

Check leakage of SVD valve and SVS valve. (Check leakage of SVDD valve and SVSS.)

Check mispiping of FS unit connecting pipe (Suction gas/Discharge gas), wiring between

FS unit and indoor unit, and connection of connectors.

Check miswiring of SVS/SVD valves.

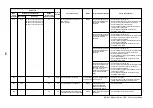

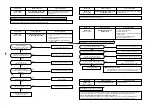

P15

P15

02: TD condition

AE

I/F

Gas leak

detection

(TD condition)

All stop

Discharge temperature TD1 or

TD2 was continuously 108°C

or higher for 10 minutes.

• Check refrigerant shortage.

• Check outdoor PMV clogging (PMV1, 2).

• Check characteristics of TD1, TD2 sensor resistance value.

• Check indoor air filter clogging.

• Check pipe clogging.

• Check SV4 circuit (Valve leakage, misinstallation)

• Check mispiping of discharge gas/suction gas main pipe.

• Check Flow selector unit.

Check leakage of SVD valve and SVS valve. (Check leakage of SVDD valve and SVSS.)

Check mispiping of FS unit connecting pipe (Suction gas/Discharge gas), wiring between

FS unit and indoor unit, and connection of connectors.

Check miswiring of SVS/SVD valves.