INSTALLATION Page

13

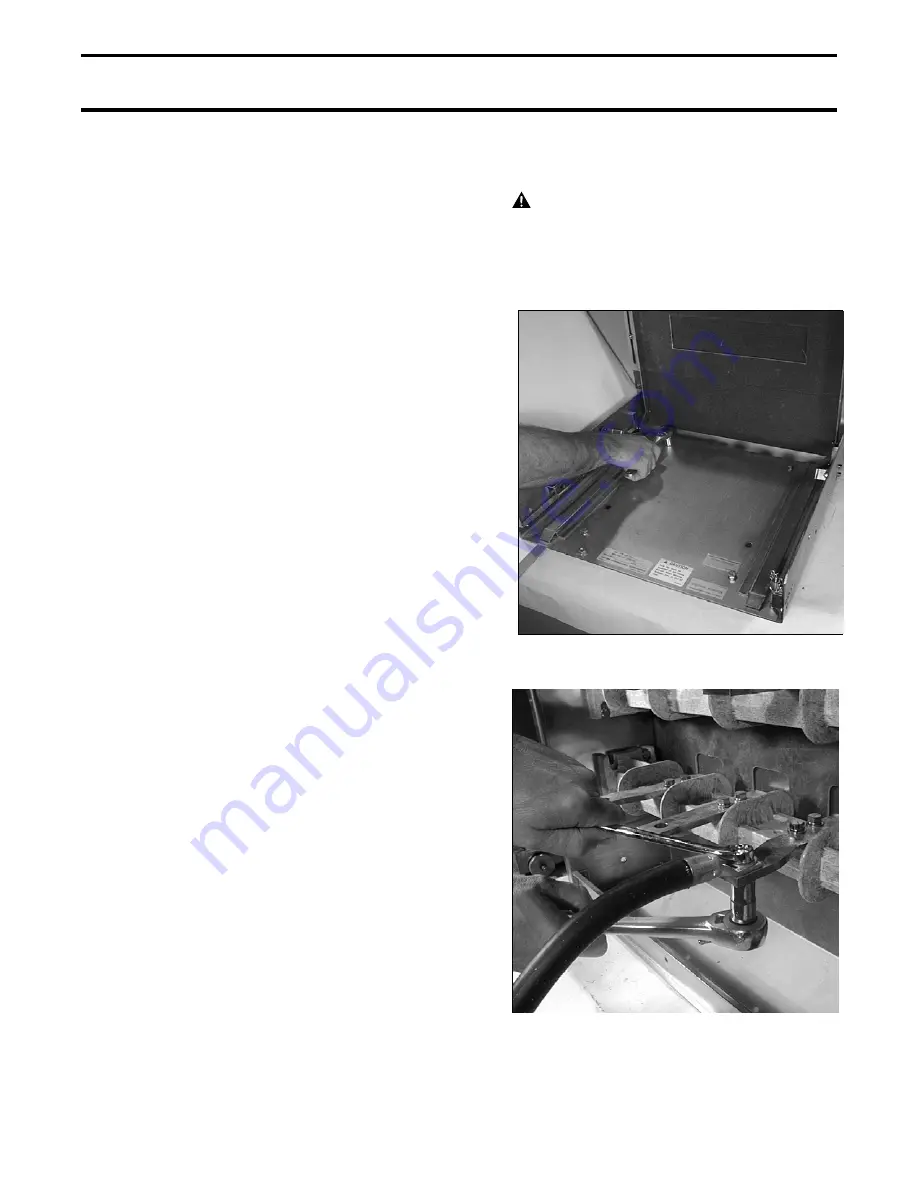

MOUNTING THE CIRCUIT BREAKER CELL

The circuit breaker cell is designed to mount to

the floor or shelf of the installation compartment.

The floor or shelf to which the cell is mounted

should be flat and level within

±

0.5 mm (

±

0.02

in.). If there are any noticeable gaps between

the cell base and the mounting surface, fill them

in using flat washers as spacers.

Fasten the cell using four (4) M8 hex head bolts

(Fig. 11). The tightening torque should be 120-

150 kgf-cm (9-11 ft-lb).

MAIN CIRCUIT CABLE CONNECTIONS

Route cables that connect to the circuit breaker

cell to avoid interference with sharp edges and

moving parts. Observe minimum bending radius

for the type of cable used.

Power cables should be braced and/or laced to

withstand short-circuit forces wherever such

cables are unsupported. Power cables should

be adequately sized to carry the maximum

continuous current in accordance with NEC

requirements and should have an adequate

voltage rating. Cables should be dressed and

terminated as appropriate to the voltage class

and cable manufacturer’s recommendations.

When terminating shielded cables, use

termination kits appropriate for the system

voltage to taper the insulation and reduce

electrical stress. Follow the manufacturer’s

installation instructions provided with the

termination kit.

Fasten the cables to the main circuit terminals

(Fasten the cables to the main circuit terminals

Fig. 12). Use 35 mm Class 8.8 M10 or M12

hex head bolts, 2 flat washers, a lock washer

and a nut. While securely preventing the nut

from rotating with a wrench, torque the bolt to

250-315 kgf-cm (18-23 ft-lb) for M10 bolts or

450-565 kgf-cm (32-41 ft-lb) for M12 bolts.

Use two wrenches to torque

the connection to prevent

applying excessive force to

the terminal that can

damage the frame.

Fig. 11 Fastening Cell to Compartment Floor

or Shelf

Fig. 12 Fastening Cables to Main Circuit

Terminals

CAUTION

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: [email protected]