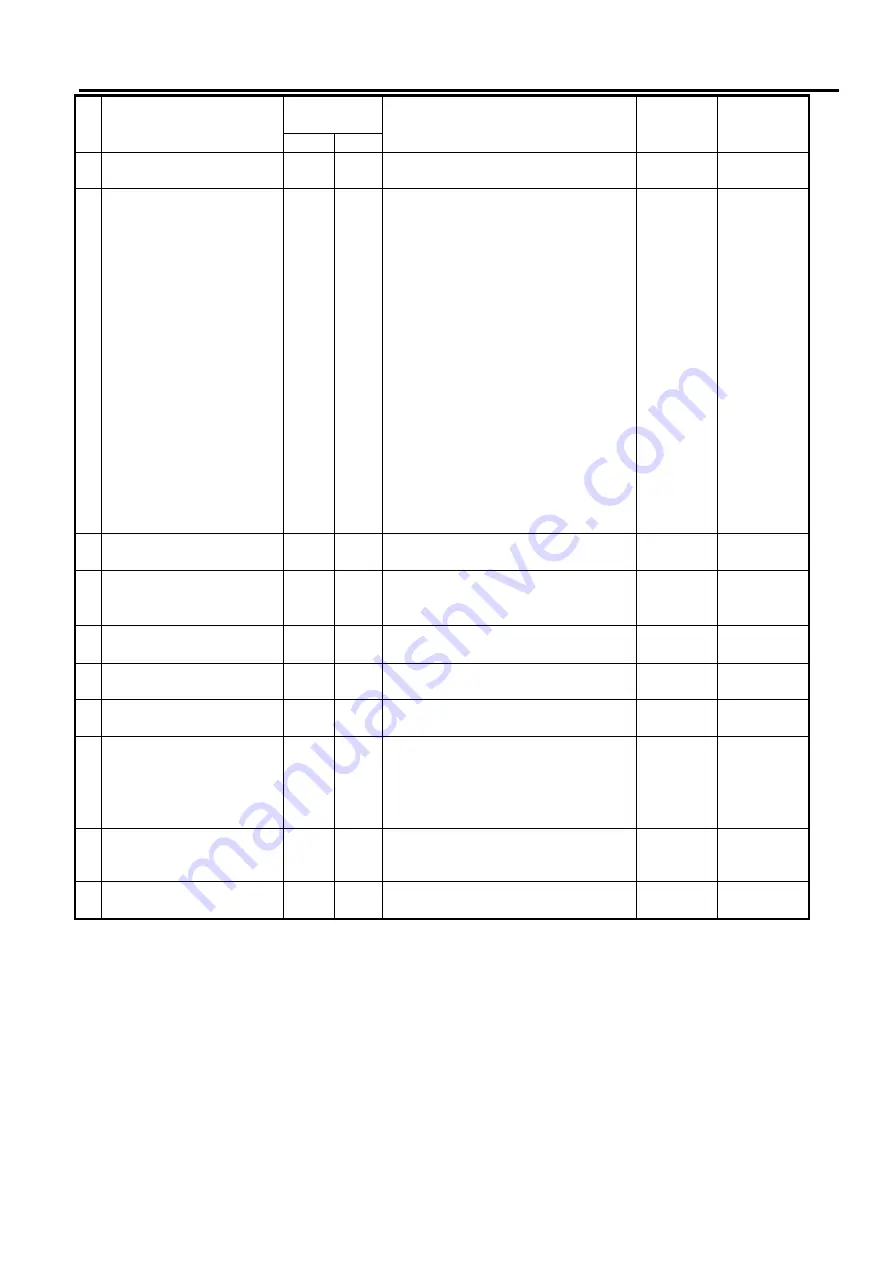

APPENDIX 1. MESSAGES AND LEDS

54

No.

LCD Message

LED Indication

Printer Status

Restoration by

RESTART key

Acceptance of

Status Request/

Reset Command

ONLINE ERROR

Yes/No

Yes/No

22

EEPROM ERROR

Data cannot be read from/written to a

backup EEPROM properly

No

No

23

SYSTEM ERROR

When the following abnormal

operations are performed, a system

error occurs:

(a) Command fetch from an incorrect

address.

(b) Access to word data at an

incorrect address.

(c) Access to long-word data at an

incorrect address.

(d) Access to the area of 80000000H

to FFFFFFFFH in the logic space

in user mode.

(e) An undefined instruction in an

area other than a delay slot was

decoded.

(f) An undefined instruction in a

delay slot was decoded.

(g) An instruction to rewrite a delay

slot was decoded.

No

No

24

DHCP CLIENT INIT

…

DHCP Client is being initialised. (Only

when the DHCP is enabled.)

-----

-----

25

RFID WRITE ERROR

The printer did not succeed in writing

data onto an RFID tag after having

retried the specified number of times.

Yes

Yes

26

RFID ERROR

The printer cannot communicate with

the RFID module.

No

Yes

27

INPUT PASSWORD

The printer is waiting for a

password to be entered.

No

No

28

PASSWORD INVALID

A wrong password was entered

three consecutive times.

No

No

29

RFID CONFIG ERROR

B-EX700-RFID-U2-EU/US-R,

B-EX700-RFID-U4-EU/US-R, U4

Module preinstall model only RFID

Module’s destination code is not

specified.

No

No

30

LOW BATTERY

( Refer to Notes)

RTC Battery is low.

No

Yes

31

INTERNAL COM ERR

A hardware error has occurred in the

internal serial interface.

No

No

NOTE:

When an error message listed above appears on the LCD display please refer to

Section 5

TROUBLESHOOTING

for a solution.