E-6

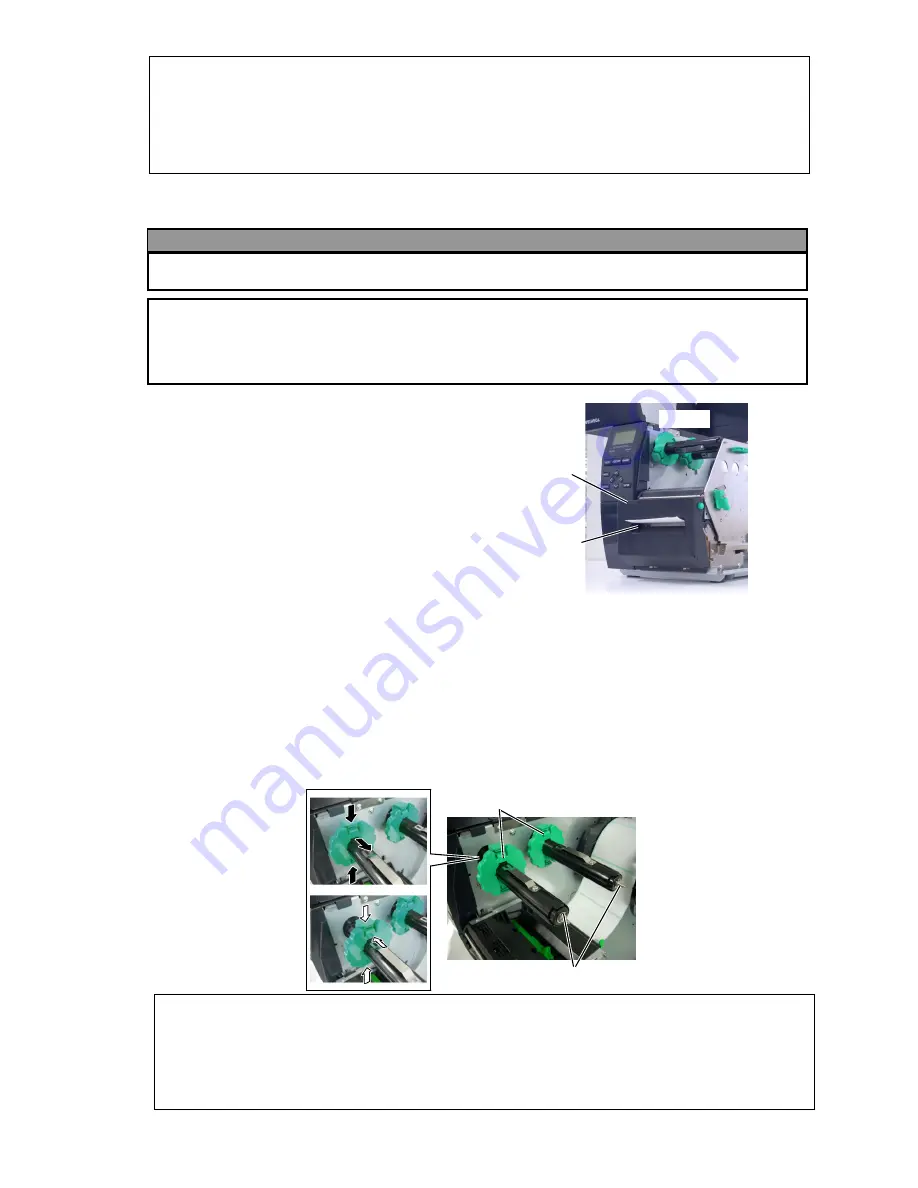

Media Outlet

Cutter Module

Loading with cutter

When the optional Cutter Module is fitted, the

media is automatically cut. A

disc

cutter

is

available as an option. Insert the leading edge

of the media into the cutter until it comes out

the Media Outlet of the Cutter Module.

3.2 Loading the Ribbon

There are two types of media available for printing on: these are thermal transfer media and direct

thermal media (a chemically treated surface). DO NOT LOAD a ribbon when using a direct thermal

media.

1. Grasp the tabs on the top and bottom of the Ribbon Stoppers and move the Ribbon Stoppers

back to the end of the Ribbon Shaft.

NOTES:

1. When attaching the ribbon stoppers, make sure that the pinchers face into the printer.

2. Be sure to remove any slack in the ribbon when printing. Printing with a wrinkled ribbon will lower the

print quality.

3. The Ribbon Sensor is mounted on the rear of the Print Head Block to detect a ribbon end. When a ribbon

end is detected, “NO RIBBON” message will appear on the display and the ERROR LED will illuminate.

WARNING!

The cutter is sharp, so care must be taken not to injure yourself when handling the cutter.

CAUTION!

1. Be sure to cut the backing paper of the label. Cutting labels will cause the glue to stick to the

cutter which may affect the cutter quality and shorten the cutter life.

2. Use of tag paper when the thickness exceeds the specified value may affect the cutter life.

NOTES:

1. Be sure to set the Selection Switch to

STANDARD/PEEL OFF

position.

2. The backing paper is easier to feed back to the Take-Up Spool if the Front Plate is removed.

3. Fit the Take-Up Clip so that the longer side of the clip is fitted into the shallow groove in the Take-Up

Spool.

4. The backing paper can be wound directly onto the Take-up Spool or a paper core.

Ribbon Stopper

Ribbon Shaft