4. TROUBLESHOOTING

ENGLISH VERSION EO1-33087

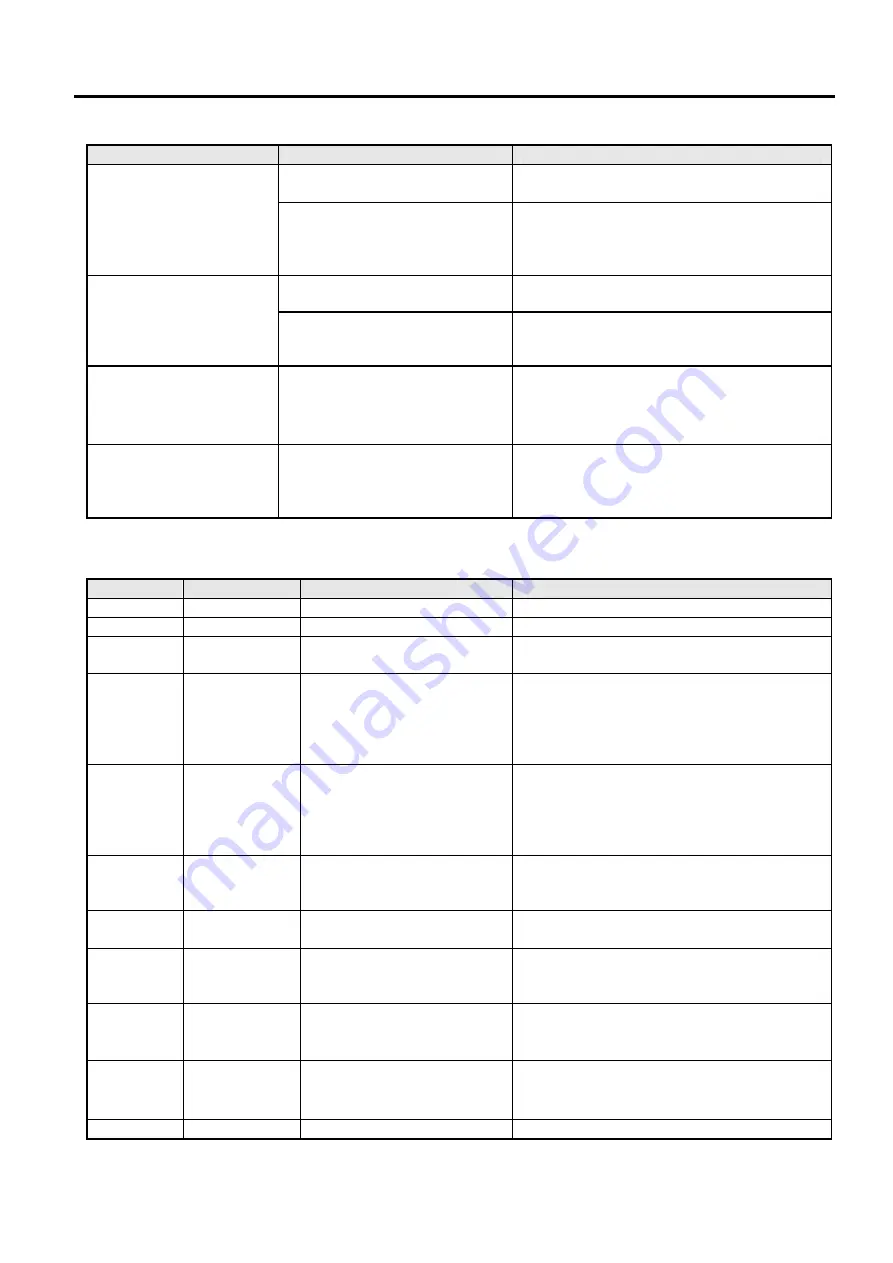

4.2 Status Lamp

E4- 2

Symptom

Cause

Solutions

The print head is dirty.

Clean the print head.

(

⇒

Section 3.1.1

)

Missing dots

The print head elements are

partly broken.

When the missing dots affect printouts, turn

off the printer and contact the nearest

TOSHIBA TEC representative to ask for

replacement of the print head.

TOSHIBA TEC approved media

is not used.

Replace the media with TOSHIBA TEC

approved one.

Labels are not separated

from the backing paper

smoothly. (When the

optional strip unit is

fitted.)

Label loading method is

incorrect.

Load the label properly. (

⇒

Section 2.7)

Peel-off issue cannot be

performed. (When the

optional strip unit is

fitted.)

The strip sensor does not work

due to intense ambient light.

Fit the Shade Plate supplied with the strip

unit.

(

⇒

Section 2.7

)

Media cannot be cut

cleanly. (When the

optional cutter unit is

fitted.)

The cuter blade has reached the

end of its useful life.

Turn off the printer and contact the nearest

TOSHIBA TEC representative to ask for

replacement of the cutter unit.

4.2 Status Lamp

Color

Status

Cause

Solutions

Green Lights

up

Stand-by

Normal

Green

Flashing fast

Communicating with a host

Normal

Green Flashing

slowly

Printing is temporarily

stopped (paused.)

Press the [FEED] Button. Printing is

resumed.

Green/Red Flashing

slowly

The print head temperature

exceeded the upper limit.

Stop printing and allow the print head to cool

until the indicator lamp lights up in green. If

the indicator lamp does not light up in green

or this problem occurs frequently, contact the

nearest TOSHIBA TEC representative.

Red

Lights up

A communication error

occurred. (Only when the

RS-232C is used.)

Turn off the power switch and back to on.

Or press the [FEED] Button. If this problem

frequently occurs, turn off the printer and

contact the nearest TOSHIBA TEC

representative.

Red

Flashing fast

A paper jam occurred.

Remove the jammed media, reload the

media, and press the [FEED] Button.

(

⇒

Section 4.3

)

Red Flashing

at

medium speed

The media is ended.

Load a new media roll and press the [FEED]

Button.

(

⇒

Section 2.7

)

Red Flashing

slowly

An issue or feed was

attempted with the top cover

opened.

Close the top cover completely, and press the

[FEED] button. Printing is resumed.

Orange

Flashing fast

A paper jam occurred din the

cutter unit. (Only when the

cutter unit is fitted.)

Remove the jammed media, reload the

media, and press the [FEED] Button.

(

⇒

Section 4.3

)

Orange Flashing

at

medium speed

The ribbon is ended.

Load a new ribbon and press the [FEED]

Button. (

⇒

Section 2.7

)

None

Unlit

The top cover is open.

Close the top cover completely

Summary of Contents for B-EV4T SERIES

Page 1: ...TOSHIBA Barcode Printer B EV4T SERIES Owner s Manual ...

Page 47: ......

Page 48: ...E EO1 33087 ...