E7-1

7. LOADING THE LABEL

ENGLISH VERSION EO1-33014

7. LOADING THE LABEL

7.1 How to Load the Liner Backed Label Roll

1

1

2

3

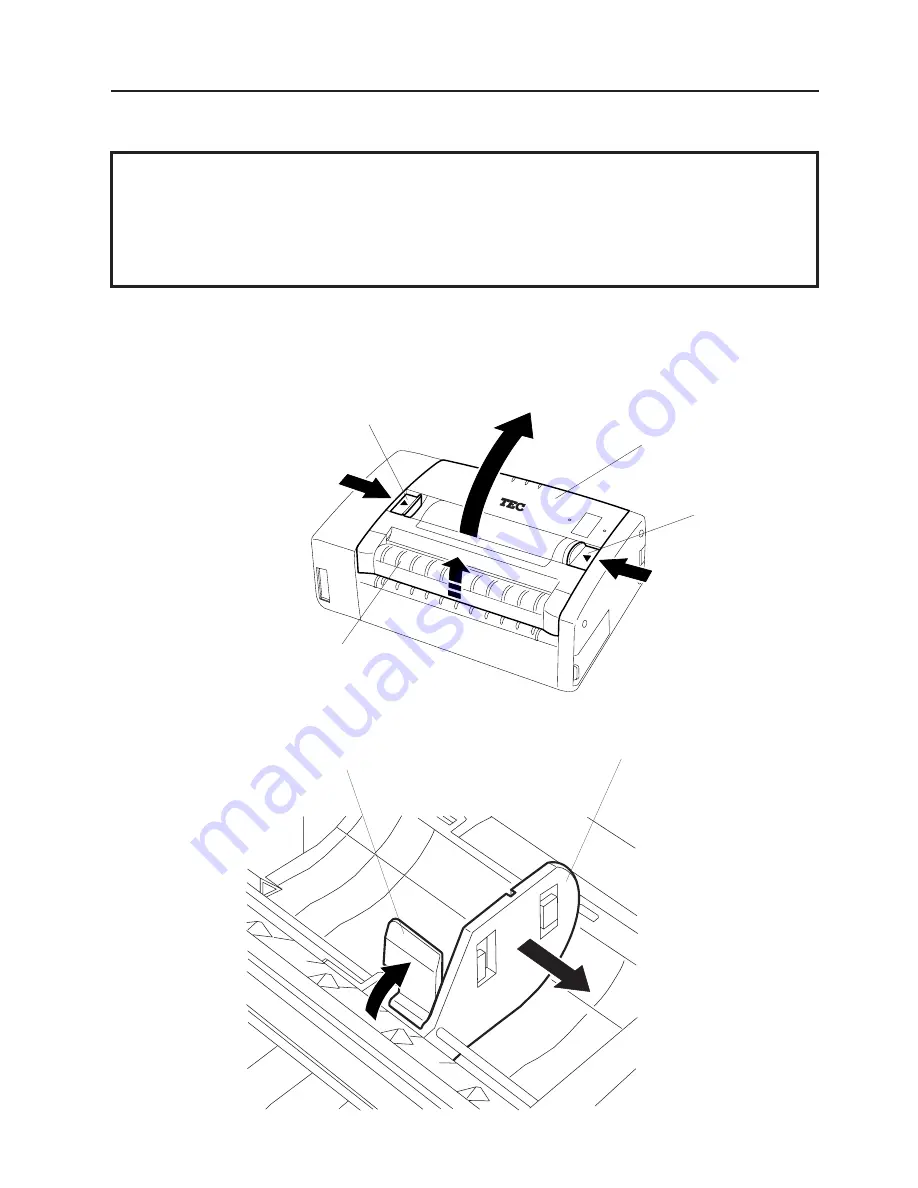

Media Cover

Media Cover

Release Catch

Media Cover Release Catch

Strip Cover

Fig. 7-1

4.

Fully raise up the release lever, and then slide the paper guide (R) to the right.

Fig. 7-2

Release Lever

Paper Guide (R)

NOTES:

1. In the strip issue mode, you should use the printer with the side in which the model name

sticker is attached downward because the backing paper is issued from the bottom of the

printer.

2. In the strip issue mode, you can tear off the backing paper using the edge of the strip cover.

3. In the batch issue mode, you can tear off the backing paper at the perforation.

7.1 How to Load the Liner Backed Label Roll

1.

Place the printer on a level surface as shown below.

2.

To unlock the media cover, press the two cover release catches in the direction of the arrows.

3.

Open the media cover by pushing up the strip cover.