25

Cleaning the Foam and Paper Elements

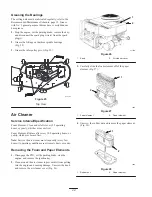

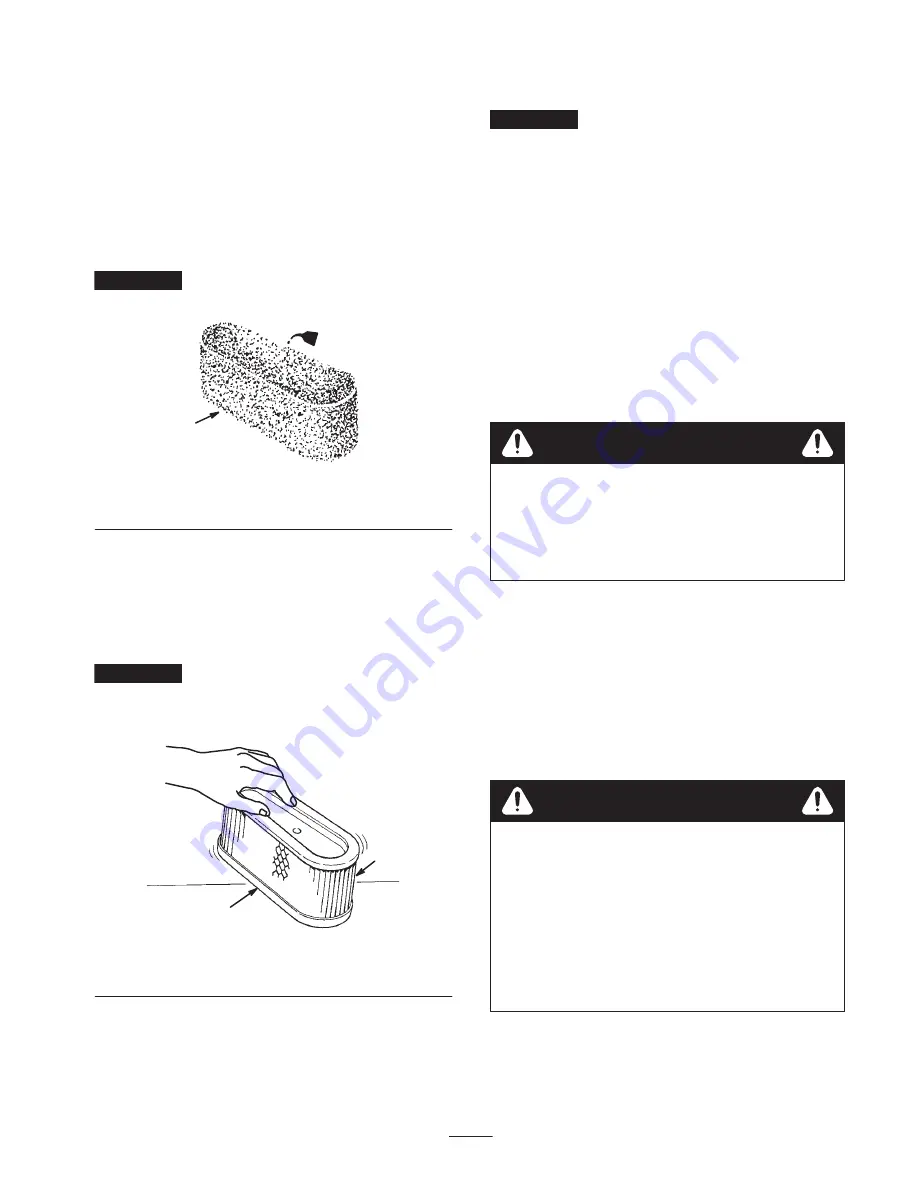

1. Foam Element

A. Wash the foam element in liquid soap and warm

water. When the element is clean, rinse it

thoroughly.

B. Dry the element by squeezing it in a clean cloth.

C. Put one or two ounces of oil on the element

(Fig. 29). Squeeze the element to distribute the oil.

Important

Replace the foam element if it is torn or

worn.

1

2

1866

Figure 29

1.

Foam element

2.

Oil

2. Paper Element

A. Lightly tap the element on a flat surface to remove

dust and dirt (Fig. 30).

B. Inspect the element for tears, an oily film, and

damage to the rubber seal.

Important

Never clean the paper element with

pressurized air or liquids, such as solvent, gas, or kerosene.

Replace the paper element if it is damaged or cannot be

cleaned thoroughly.

1

2

1867

Figure 30

1.

Paper element

2.

Rubber seal

Installing the Foam and Paper Elements

Important

To prevent engine damage, always operate

the engine with the complete foam and paper air cleaner

assembly installed.

1. Carefully slide the foam element onto the paper air

cleaner element (Fig. 27).

2. Slide the air cleaner assembly onto the long rod. Now

screw the rubber nut finger-tight against the air cleaner

(Fig. 28).

Note: Make sure the rubber seal is flat against the air

cleaner base.

3. Install the air cleaner cover and knob (Fig. 26). Tighten

the knob securely.

Servicing the Battery

Battery posts, terminals, and related accessories

contain lead and lead compounds, chemicals

known to the State of California to cause cancer

and reproductive harm. Wash hands after

handling.

Warning

Check the electrolyte level in the battery every 25 hours.

Always keep the battery clean and fully charged. Use a

paper towel to clean the battery case. If the battery

terminals are corroded, clean them with a solution of four

parts water and one part baking soda. Apply a light coating

of grease to the battery terminals to prevent corrosion.

Voltage: 12 v

Removing the Battery

Battery terminals or metal tools could short

against metal tractor components causing sparks.

Sparks can cause the battery gasses to explode,

resulting in personal injury.

•

When removing or installing the battery, do not

allow the battery terminals to touch any metal

parts of the tractor.

•

Do not allow metal tools to short between the

battery terminals and metal parts of the tractor.

Warning

1. Disengage the PTO, set the parking brake, stop the

engine, and remove the key.

2. Tip the seat forward to see the battery.

Summary of Contents for Z16-44 TimeCutter

Page 6: ...6 ...

Page 7: ...7 Slope Chart ...

Page 8: ...8 ...

Page 11: ...11 104 8014 1 Parking brake 104 5091 104 8088 ...

Page 38: ...38 ...

Page 39: ...39 ...